Soldering Station The Ultimate Guide to Choosing a Top Rated One

Introduction

Welcome to our comprehensive guide on soldering stations. Whether you’re an electronics hobbyist, a professional working with small electronics, or a DIY enthusiast, having the right soldering station can make a significant difference in the quality and efficiency of your work. In this article, we will explore the key components of a soldering station, the benefits of using a top-rated soldering station, how to choose the best one for your needs, top-rated soldering station brands, tips for maintaining your soldering station, and more. Let’s dive in to understand why a top-rated soldering station is an essential tool for anyone working with small electronics.

What is a Soldering Station?

Understanding Soldering Stations

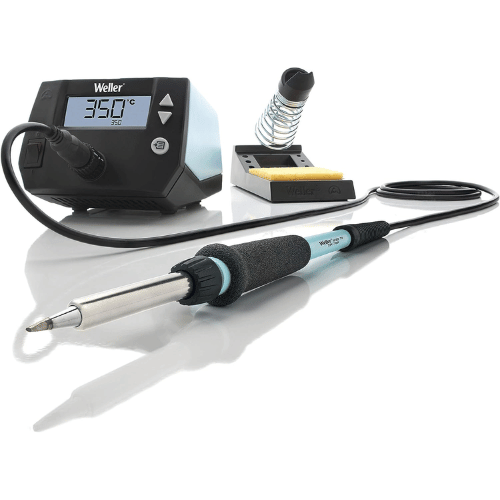

A soldering station is a vital tool used in the electrical and electronics industry for joining or repairing small electronic components, wires, and circuit boards. It consists of three main components: a soldering iron, a control unit, and a stand. Let’s delve deeper into the details of each component:

- The soldering iron is the primary tool used to apply heat to the joint that needs to be soldered. It is equipped with a heated metal tip, often composed of copper, that heats up when the station is powered on.

- Modern soldering irons feature adjustable temperature settings, allowing the user to select the appropriate temperature for different soldering tasks. This level of control ensures the solder melts at the right temperature without damaging the components.

- The control unit is the brain of the soldering station, responsible for regulating the temperature of the soldering iron. This precise temperature control is crucial for achieving consistent and high-quality solder joints.

- Advanced soldering stations utilize digital control units, offering precise temperature adjustments and display features, enabling users to monitor and adjust the temperature with accuracy.

- The stand provides a secure place to keep the soldering iron when it is not in use. It also ensures safety by preventing accidental burns and damage to the work surface.

- Some stands come with a cleaning sponge to keep the soldering iron tip clean and free from oxidation, ensuring optimal performance during soldering.

Key Components of a Soldering Station

When it comes to soldering stations, understanding the key components is essential for efficient and reliable soldering. The main components of a soldering station include:

- Soldering Iron: This is the primary hand tool used to heat the solder. It consists of a handle, a heating element, and a tip designed for specific soldering tasks. The choice of soldering iron depends on the type of soldering work, such as fine electronics soldering or larger joint soldering.

- Control Unit: The control unit is responsible for adjusting and regulating the temperature of the soldering iron. It allows the user to set the desired temperature for different soldering applications, ensuring precise and consistent heating.

- Soldering Stand: When the soldering iron is not in use, it should be placed on a soldering stand to prevent any accidental contact with flammable materials or surfaces. The stand also holds the iron securely in place and provides easy access during soldering tasks.

- Cleaning Accessories: Keeping the soldering iron tip clean is crucial for optimal performance. For this purpose, a sponge or brass wire is used to remove excess solder and oxidation from the tip, maintaining its effectiveness during soldering operations.

These components work in harmony to create an ideal environment for soldering small electronic components, ensuring precision and reliability in the soldering process.

Why You Need a Top Rated Soldering Station

Benefits of Using a Top Rated Soldering Station

Using a top-rated soldering station offers several advantages:

- Precise Temperature Control: A top-rated soldering station ensures precise temperature control, which is crucial for different types of solder and electronic components. This level of control minimizes the risk of overheating sensitive components and enhances the quality of soldering joints.

- Ergonomic Designs: Many top-rated soldering stations feature ergonomic designs, tailored to provide comfort and reduce fatigue during extended soldering sessions. These designs often include adjustable stands, well-positioned controls, and easy-to-grip handles.

- Safety Features: Advanced safety features, such as automatic standby modes, heat-resistant insulation, and secure tip holders, are commonly integrated into top-rated soldering stations. These features are essential for preventing accidents and ensuring user safety.

- Consistent Performance: Top-rated soldering stations deliver consistent and reliable performance, making them suitable for professional and hobbyist use alike. Their ability to maintain a stable temperature and provide uniform heating results in high-quality soldering outcomes.

How to Choose a Top Rated Soldering Station

Considerations for Selecting the Right Soldering Station

When choosing the right soldering station for your needs, it’s essential to consider a range of factors that can significantly impact your soldering experience. Below are the key considerations to keep in mind:

- Temperature Range: A top-rated soldering station should offer a wide temperature range to accommodate various soldering tasks. Look for a station that allows precise temperature control for different types of solder and electronic components.

- Heat-Up Time: The heat-up time of a soldering station determines how quickly it can reach the desired temperature. Consider a station with rapid heat-up capabilities, which can save time and improve efficiency during soldering projects.

- Wattage: Wattage plays a crucial role in determining the heat output of the soldering station. Higher wattage stations can handle more substantial soldering tasks and provide better thermal recovery, especially when working with larger components.

- Ease of Maintenance: Look for a soldering station that is easy to maintain and clean. Stations with accessible parts and clear maintenance instructions can extend the lifespan of the equipment and ensure consistent performance over time.

- Tip Compatibility: An ideal soldering station should be compatible with a variety of soldering tips to suit different applications. Having the flexibility to use different tip shapes and sizes enhances the versatility of the station for diverse soldering projects.

- Ergonomic Design: Consider the ergonomic aspects of the soldering station, such as the handle design, weight distribution, and user comfort. An ergonomic station can reduce hand fatigue and discomfort, especially during prolonged soldering sessions.

Top Features to Look for in a Soldering Station

- Digital Temperature Control: Look for a soldering station that offers precise control over the temperature settings. This allows you to solder different types of components with varying heat requirements.

- Rapid Heat-Up: A soldering station with rapid heat-up capability ensures that you can start working on your projects without lengthy waiting times. It improves efficiency and reduces downtime.

- Interchangeable Tips: The ability to change soldering tips is essential for versatility in soldering tasks. Different tips are suited for specific soldering applications, and having the option to interchange them provides flexibility.

- Heat-Resistant Soldering Iron Stand: Ensure that the soldering station comes with a heat-resistant stand to safely place the soldering iron during and after use. This prevents accidental burns and damage to work surfaces.

- Safety Features: When selecting a soldering station, prioritize safety features such as automatic shut-off and overheat protection. These features offer peace of mind and prevent potential accidents during soldering operations.

The top features to look for in a soldering station play a critical role in enhancing precision, efficiency, and safety in soldering tasks. By considering these features, you can ensure that the soldering station meets your requirements and supports your projects with the necessary functionality.

Factors to Consider When Comparing Soldering Stations

- Temperature Stability: The temperature stability of a soldering station is crucial for precision soldering. It is essential to ensure that the station can maintain a consistent and accurate temperature throughout the soldering process, minimizing the risk of overheating or cold solder joints.

- Wattage: When comparing soldering stations, it’s important to consider the wattage of the station. Higher wattage allows for faster heating and recovery times, making it suitable for larger jobs and heavy-duty soldering applications.

- Compatibility with Different Solder Types: A versatile soldering station should be compatible with various solder types, including lead-free and traditional lead-based solders. This compatibility ensures that the station can accommodate different soldering requirements and materials.

- Ease of Maintenance: An efficient soldering station should be easy to maintain, with accessible cleaning and replacement of components such as tips and filters. Regular maintenance prolongs the station’s lifespan and ensures consistent soldering performance.

- User-Friendly Controls: User-friendly controls enhance the overall soldering experience. Intuitive interface, adjustable settings, and ergonomic design contribute to increased productivity and ease of use.

- Manufacturer’s Reputation: Considering the reputation of the manufacturer is essential when comparing soldering stations. Reputable manufacturers often offer reliable products, warranty support, and access to technical resources.

- Availability of Accessories and Replacement Parts: It is beneficial to assess the availability of accessories and replacement parts for the soldering station. Having easy access to genuine accessories and parts ensures seamless operations and timely maintenance.

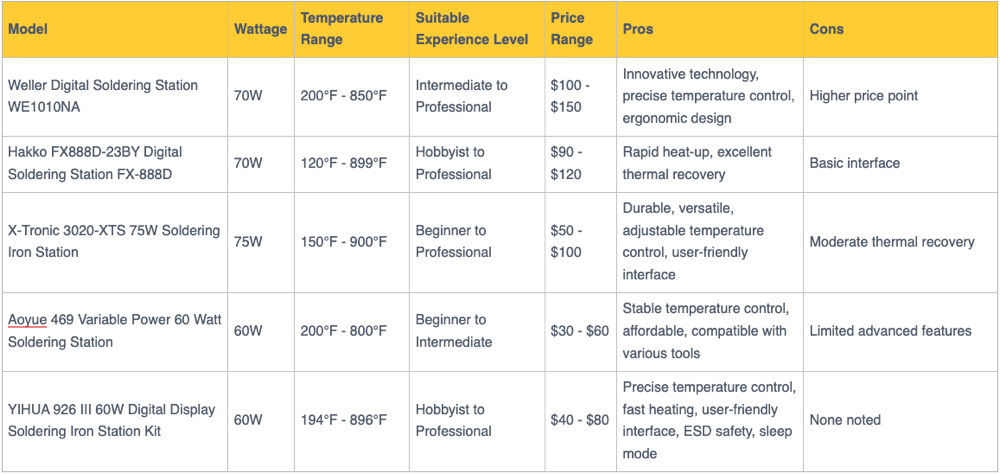

Popular Soldering Stations Comparison Table

Top Rated Soldering Station Brands

Overview of Leading Soldering Station Brands

Leading Soldering Station Brands: A Comprehensive Overview

- Weller: Weller soldering stations are known for their innovative technology and precision. They offer a wide range of soldering stations suitable for various applications, including electronics, industrial manufacturing, and DIY projects. The Weller Digital Soldering Station, for example, is highly regarded for its temperature control and ergonomic design.

- Hakko: Hakko is a leading brand in the soldering industry, recognized for its high-performance soldering stations. Hakko’s FX-888D Digital Soldering Station is a popular choice among professionals and hobbyists due to its rapid heat-up and excellent thermal recovery.

- X-Tronic: X-Tronic soldering stations are known for their durability and versatility. The X-Tronic Model #3020-XTS Digital Display Soldering Iron Station offers adjustable temperature control and a sleek, user-friendly interface, making it suitable for a wide range of soldering tasks.

- Aoyue: Aoyue specializes in soldering and desoldering equipment, offering reliable and affordable soldering stations. The Aoyue 469 Variable Power 60-Watt Soldering Station is a popular choice due to its stable temperature control and compatibility with various soldering tools.

- YIHUA: The YIHUA 939D+ Digital Soldering Station offers precise temperature control (194°F-896°F), fast heating, and a user-friendly digital interface. It’s versatile for various soldering tasks, features ESD safety, and has a sleep mode for energy efficiency. Compatible with multiple tips and accessories, it’s ideal for hobbyists and professionals.

- Kester: Kester is renowned for its high-quality soldering materials and equipment. The Kester 951 Soldering Flux Pen and Kester 951 Liquid Soldering Flux are trusted products used in conjunction with Kester soldering stations to ensure precise and reliable soldering results.

Tips for Maintaining Your Soldering Station

How to Properly Maintain a Soldering Station

To properly maintain a soldering station and ensure its longevity, optimal performance, and safety, it is essential to follow a comprehensive maintenance routine. Below are detailed steps and guidelines for maintaining your soldering station:

- Cleaning the Soldering Iron Tip: Regularly clean the soldering iron tip to prevent oxidation and ensure efficient heat transfer. Use a brass wire sponge, solder tip cleaner, or a damp sponge to clean the tip during and after use.

- Replacing Worn-out Tips: Keep a selection of replacement tips suitable for different soldering tasks. When a tip becomes worn or deformed, replace it promptly to maintain high-quality solder joints and prevent potential damage to sensitive electronic components.

- Station and Component Maintenance: Keep the soldering station and its components free from dust and debris to maintain optimal performance. Use a soft brush or compressed air to remove dust and dirt from the station, soldering iron, and other accessories.

- Calibration and Maintenance: Follow the manufacturer’s guidelines for calibration and maintenance to ensure the accuracy and reliability of the station. This may involve periodic calibration of temperature settings, inspection of connections, and testing of safety features.

- Proper Storage: When the soldering station is not in use, store it in a clean and dry environment to prevent contamination and damage. Use a designated storage area or case to protect the station and accessories from environmental factors.

Conclusion

In conclusion, a top-rated soldering station is an indispensable tool for anyone working with small electronics. It offers precision, reliability, and ease of use, making it essential for achieving high-quality soldering results. By understanding the key components, benefits, considerations for selection, top brands, and maintenance tips, you can make an informed decision when choosing the best soldering station for your needs. Remember, the right soldering station can significantly impact the quality and efficiency of your electronic projects, so choose wisely!