Solving Soldering Iron Issues Like a Pro

Introduction

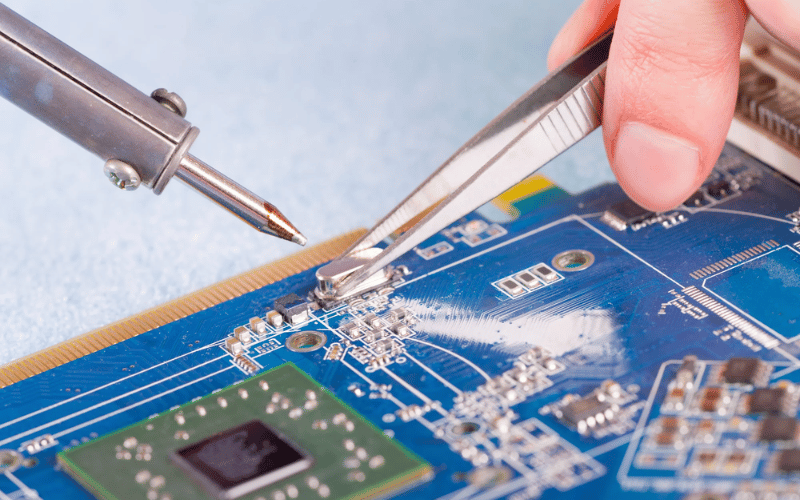

Soldering irons are essential tools for electronics hobbyists, technicians, and professionals. They are used to join metal components together, create electrical connections, and perform intricate soldering tasks. However, like any tool, soldering irons can develop issues that hinder their performance and effectiveness. In this comprehensive guide, we will explore common soldering iron issues, preventive measures, troubleshooting techniques, and tips for enhancing soldering skills. Whether you’re a novice or an experienced user, this guide aims to equip you with the knowledge to address soldering iron issues effectively.

Understanding Soldering Iron Issues

What is a Soldering Iron?

A soldering iron is a hand tool with a heated metal tip that is used to melt and apply solder. It is commonly utilized in electronics assembly, DIY projects, jewelry making, and stained glass work. Soldering irons come in various types, including pencil, gun, and station irons, each serving specific purposes based on their design and features.

Common Soldering Iron Issues

Common Soldering Iron Issues

- Common soldering iron issues arise due to a variety of factors, leading to challenges in achieving high-quality soldering results.

- Inconsistent temperature is a common problem encountered with soldering irons. This can result in difficulties in melting the solder material uniformly, leading to unreliable solder joints.

- Poor soldering connections can occur due to insufficient heating or improper technique. This can lead to weak connections and potential electrical failures.

- Tip oxidation is a frequent issue that affects the soldering iron’s performance. Oxidation can hinder heat transfer and compromise the integrity of soldered joints, resulting in reduced quality and durability.

- Another common problem is faulty heating elements, which can lead to a range of issues such as temperature fluctuations and incomplete solder melting.

Addressing these common soldering iron issues is vital for ensuring the effectiveness and reliability of soldered components and electrical connections. By taking proactive measures to minimize these issues, professionals can achieve consistent, high-quality soldering results and enhance the longevity of electronic devices and circuits.

Importance of Addressing Soldering Iron Issues

Addressing soldering iron issues is crucial for maintaining the efficiency, reliability, and safety of soldering operations. It also plays a significant role in ensuring the integrity of electrical connections, enhancing the quality of soldered joints, and optimizing the performance of soldering equipment. By addressing these issues, users can significantly contribute to the longevity and durability of soldering iron components and accessories, ultimately improving the overall soldering process.

- Understanding the Impact of Soldering Iron Issues

- Identification and Resolution of Common Soldering Iron Problems

- Maximizing Efficiency and Safety Through Proactive Maintenance

Preventive Measures for Soldering Iron Issues

Cleaning and Maintenance Tips

Regular cleaning and maintenance are crucial to prevent soldering iron issues. It’s important to keep the soldering iron in top condition to ensure optimal performance and lifespan. Here are some comprehensive cleaning and maintenance tips:

- Cleaning the Soldering Iron Tip: Use a brass wire sponge or tip cleaner to remove excess solder and oxidation from the tip. This helps to maintain the heat transfer efficiency and prevents contamination of solder joints.

- Ensuring Proper Storage: Store the soldering iron in a dry and clean environment to protect it from moisture and dust. A dedicated storage case or stand can prevent damage and maintain the integrity of the tool.

- Using High-Quality Solder and Flux: Quality materials contribute to reliable soldering joints and reduce the risk of issues like cold solder joints or poor connectivity.

- Proper Soldering Techniques: Mastering the right soldering techniques, such as correct temperature settings, solder application, and joint inspection, is essential for efficient and high-quality soldering work.

Proper Storage Practices

Proper Storage Practices

Proper storage of soldering irons is crucial for maintaining their quality and longevity. Here are some detailed practices to ensure the proper storage of soldering irons:

- Use designated holders or stands that provide a safe and secure place for the tool when not in use

- Store the soldering iron in a clean and dry environment to prevent moisture-related damage

- Ensure the tip is consistently clean, tinned, and free from oxidation to optimize soldering performance

- Keep the soldering iron away from dust and contaminants to avoid issues with tip oxidation and poor soldering performance

- Inspect the storage area regularly to maintain an optimal storage environment for the soldering iron

Troubleshooting Soldering Iron Issues

Faulty Heating Element

A faulty heating element can lead to inconsistent temperature, slow heat-up times, and overall poor performance of the soldering iron. Resolving this issue may involve repairing or replacing the heating element, depending on the severity of the damage and the type of soldering iron.

Several factors can contribute to the malfunction of a heating element in a soldering iron. Understanding these causes can help soldering enthusiasts troubleshoot and prevent future issues. Some common causes include:

- Overheating: Exposing the soldering iron to excessively high temperatures can damage the heating element.

- Corrosion: Rust or corrosion on the heating element can hinder its ability to generate and maintain heat consistently.

- Physical Damage: Dropping or mishandling the soldering iron can cause physical damage to the heating element, leading to performance issues.

Identifying the early signs of a faulty heating element can help prevent further damage and maintain the performance of the soldering iron. Some common indicators include:

- Inconsistent Temperature: A heating element in disrepair may lead to inconsistent heat output, affecting the quality of soldering work.

- Sooty Residue: Presence of black soot on the heating element is a sign of incomplete combustion, indicating a potential issue.

- Slow Heat-Up Times: A degraded heating element may result in prolonged heat-up times, causing inconvenience during soldering tasks.

Poor Soldering Connections

Poor soldering connections can result from inadequate soldering techniques, insufficient heat, or contaminated solder. Identifying and rectifying poor soldering connections involves:

- Re-soldering the joints with the correct temperature and soldering iron tip size.

- Ensuring proper flux application to promote good wetting and adhesion of the solder.

- Employing techniques such as drag soldering or drag soldering for surface mount components to enhance the strength and reliability of the connections.

- Inspecting the joints for proper fillet formation and shiny appearance, indicating a good solder connection.

Tips for Identifying and Resolving Issues

When it comes to identifying and resolving soldering iron issues, a systematic and comprehensive approach to troubleshooting is essential. By taking the time to thoroughly inspect, test, and diagnose problems, individuals can effectively resolve issues and improve the overall performance of the soldering iron. Let’s delve into more detailed tips for identifying and resolving soldering iron issues:

- Visual Inspection: Visual inspection serves as the initial step in the troubleshooting process. It involves closely examining the soldering iron for visible damage, loose connections, or signs of wear. Carefully check the power cord, handle, and soldering tip for any abnormalities that could indicate potential issues, such as fraying in the power cord, cracks in the handle, or erosion on the soldering tip. Any of these observations could be indicative of underlying problems that need attention.

- Temperature Testing: Temperature testing is a crucial aspect of identifying soldering iron issues. Using a temperature gauge or thermal imaging tool, measure the heat output of the soldering iron and verify that it matches the set value. It is also important to ensure that the temperature remains consistent during operation. Any fluctuations or deviations from the expected temperature range could signal a malfunction, and further investigation would be necessary to identify the root cause.

- Heat-up Time: The heat-up time of a soldering iron is another key factor to assess during troubleshooting. It is important to determine whether the soldering iron reaches the desired temperature promptly. A significant delay in heating up or an inability to reach the specified temperature may signal a heating element or power supply problem. Additionally, observing the heat-up pattern can provide insights into the performance of the soldering iron.

- Electrical Testing: Employing a multimeter for electrical testing is a valuable method for identifying underlying issues with the soldering iron. Through this testing, the continuity of the power cord can be checked, and the resistance of the heating element can be measured. Furthermore, the functionality of the temperature control components can be verified. Electrical testing often reveals hidden issues that may contribute to performance problems, such as faulty components, damaged wiring, or malfunctioning temperature control.

- Professional Assistance: In cases where issues are complex or persistent, seeking the expertise of a professional technician or electrician is crucial. These specialists can conduct advanced diagnostics to identify elusive problems and provide tailored solutions for the specific soldering iron model. Their expertise and insights can be invaluable in resolving intricate issues that may be beyond the scope of standard troubleshooting methods.

- Regular Maintenance: Implementing a routine maintenance schedule for the soldering iron is imperative for preventing issues and ensuring optimal performance. This includes cleaning the soldering tip, inspecting and replacing damaged components, and lubricating moving parts. Regular maintenance not only prolongs the lifespan of the soldering iron but also minimizes the occurrence of performance-related problems.

- Utilizing Proper Soldering Techniques: Adhering to correct soldering techniques is fundamental for preventing issues and maintaining the efficiency of the soldering iron. This involves using the appropriate soldering temperature, employing the right soldering iron tip, and ensuring proper solder joint quality. By utilizing proper soldering techniques, individuals can minimize the risk of overheating, cold solder joints, and other common soldering issues.

Enhancing Soldering Skills to Prevent Issues

Proper Soldering Techniques

Mastering proper soldering techniques is essential for ensuring reliable and durable connections. By employing a variety of techniques such as through-hole and surface mount soldering, soldering professionals can achieve precise and effective results.

Here are some key techniques to consider:

- Through-Hole Soldering: This technique involves soldering components on one side of a PCB and feeding the leads through the holes to solder the other side. It requires careful attention to avoid solder bridges and ensure proper joint formation.

- Surface Mount Soldering: Surface mount components are soldered directly onto the surface of the PCB. It requires attention to detail and the use of specialized tools to achieve proper alignment and solder connections.

- Drag Soldering: This method involves dragging a small bead of solder across multiple pins to create the connection. It requires finesse and precision to avoid excessive solder and bridging.

- Reflow Soldering: Reflow soldering involves quickly heating the entire assembly to create solder connections. This technique requires proper temperature control and attention to the reflow profile for optimal results.

- Solder Bridge Removal: Removing unwanted solder bridges is a crucial skill that ensures the integrity and functionality of the circuit.

By mastering these techniques and paying attention to the specifics of each soldering approach, professionals can minimize the occurrence of soldering issues and achieve consistent, high-quality results. It is important to continue expanding one’s skills and staying updated on the latest advancements in soldering technology.

Using the Right Tools and Equipment

Effective soldering relies on the use of the right tools and equipment, which significantly impacts the quality and efficiency of the soldering process. By employing the appropriate soldering iron, solder, flux, and supplementary tools, one can achieve superior results while minimizing the risk of errors and defects. Let’s delve into the key tools and equipment essential for successful soldering:

- Soldering Iron: Invest in a temperature-controlled soldering iron that suits the specific requirements of your soldering projects. These irons ensure precise and consistent heat, enabling better control and accuracy during the soldering process. Additionally, consider the ergonomics of the soldering iron to prevent hand fatigue during extended soldering tasks.

- Solder: Quality solder is crucial for achieving strong and reliable connections. Look for lead-free solder with a flux core to minimize the risk of toxic fumes. The diameter of the solder should match the scale of the soldering work.

- Flux: Using the right flux is vital for efficient soldering. It cleans and preps the surfaces to be soldered, promoting strong and durable joints. Select flux that is compatible with the materials being soldered and ensure it is applied sparingly for optimal results.

- Soldering Station: An ergonomic soldering station provides a stable and organized work environment. It should feature a secure holder for the soldering iron, adjustable temperature settings, and integrated safety features to prevent overheating and electrical hazards. A well-designed soldering station enhances workflow and safety, contributing to the overall efficiency of soldering tasks.

- Cleaning Tools: Keep your soldering equipment in top condition by using cleaning tools such as brass sponges, tip cleaners, and solvents. Regular maintenance of the soldering iron and related equipment ensures consistent performance and prolongs their lifespan.

Conclusion

In conclusion, this comprehensive guide has shed light on the nuances of soldering iron issues, preventive measures, troubleshooting techniques, and strategies for honing soldering skills. By understanding the common issues that affect soldering irons and adopting proactive measures, users can ensure the reliability, longevity, and performance of their soldering equipment. Furthermore, enhancing soldering skills and utilizing the right tools and techniques are pivotal in preventing issues and achieving optimal soldering results.