Soldering Iron for Electronics: The Ultimate Buyer's Guide

Introduction

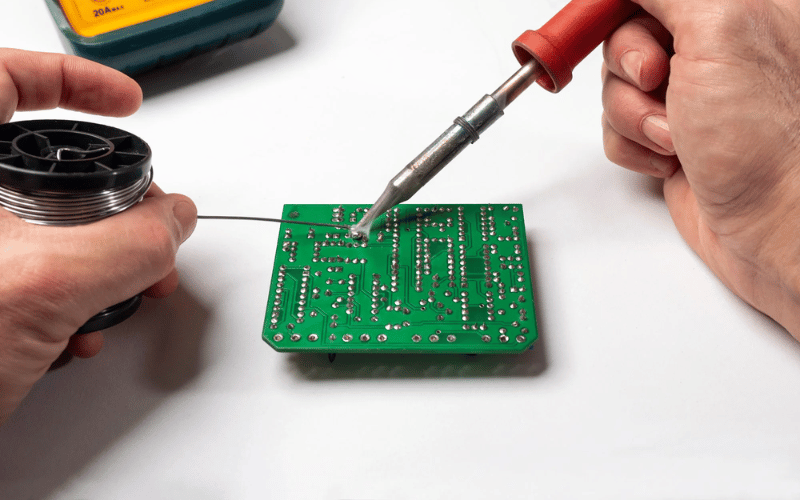

Soldering irons are essential tools for anyone working with electronics, whether it’s for repairing a circuit board or creating a DIY electronic project. The right soldering iron can make a significant difference in the quality and reliability of your work. In this comprehensive guide, we will explore the different types of soldering irons, key considerations for choosing the best one, best practices for soldering electronics, common mistakes to avoid, a comparative analysis of top soldering irons, and how to find the best soldering iron for electronics. By the end of this article, you’ll have a deep understanding of the factors that make a soldering iron stand out, allowing you to make an informed decision for your electronic soldering needs.

Types of Soldering Iron for Electronics

1. Soldering Pencil

The soldering pencil, also known as a soldering iron pen, is a popular choice for hobbyists and professionals due to its versatility and precision. It usually features a slim, pen-like design with a pointed tip, making it suitable for intricate soldering tasks in electronics. The compact nature of the soldering pencil allows for easy maneuvering, especially when working with small circuit boards and delicate components.

However, there is more to the soldering pencil than just its size and shape. Let’s take a closer look at the features and benefits of this type of soldering iron.

One of the key features of a soldering pencil is its temperature control. Most models come with adjustable temperature settings, allowing you to choose the right temperature for your specific soldering needs. This is especially important when working with delicate components that require a lower temperature to avoid damage.

Some soldering pencils also come with a built-in temperature display, making it easier to monitor and adjust the temperature as needed.

Another advantage of the soldering pencil is its quick heating time. Most models can reach their maximum temperature in just a few seconds, allowing you to start soldering right away. This is especially useful for professionals who need to complete their work efficiently.

Many soldering pencils come with interchangeable tips, allowing you to switch between different sizes and shapes depending on your soldering needs. This makes the soldering pencil a versatile tool that can be used for a variety of soldering tasks.

Some models also come with specialized tips for specific soldering tasks, such as fine-point tips for precision work or chisel tips for larger joints.

The compact and lightweight design of the soldering pencil makes it highly portable. This is especially useful for hobbyists who may need to work on their projects in different locations. The small size also makes it easier to store when not in use.

Compared to other types of soldering irons, the soldering pencil is generally more affordable. This makes it a great option for beginners or hobbyists who may not want to invest in a more expensive soldering station.

Many soldering pencils come with safety features such as auto shut-off or heat-resistant handles to prevent accidents and injuries. These features make the soldering pencil a safer option for both professionals and beginners.

The soldering pencil is a versatile and affordable option for soldering in electronics. Its compact size, temperature control, quick heating time, interchangeable tips, portability, and safety features make it a popular choice among hobbyists and professionals alike. Consider adding a soldering pencil to your toolkit for all your soldering needs.

2. Soldering Station

A soldering station, also referred to as a soldering iron station, is a complete soldering setup that includes a base unit with variable temperature controls and interchangeable soldering iron tips. This type of soldering iron provides consistent heat and temperature regulation, offering the user more control over the soldering process. Soldering stations are ideal for professional electronics work and projects that require precise temperature adjustments.

But what exactly is a soldering station and how does it differ from other types of soldering irons? Let’s take a closer look at this essential tool for electronics enthusiasts and professionals.

A soldering station typically consists of three main components:

- Base Unit: This is the main control unit of the soldering station. It houses the power supply, temperature control, and other features.

- Soldering Iron: The soldering iron is the hand-held tool that is used to apply heat to the solder joint. It is connected to the base unit via a cable and can be easily replaced with different types of soldering iron tips.

- Sponge or Brass Tip Cleaner: This is used to clean the soldering iron tip and remove any excess solder or debris.

So why should you invest in a soldering station instead of a basic soldering iron? Here are some advantages that a soldering station offers:

- Temperature Control: Unlike a basic soldering iron, a soldering station allows you to adjust the temperature according to your specific needs. This is especially useful when working with delicate electronic components that require precise temperature control.

- Consistent Heat: Soldering stations provide a stable and consistent heat output, which is crucial for achieving clean and reliable solder joints.

- Interchangeable Tips: With a soldering station, you can easily swap out different types of soldering iron tips to suit your specific project needs. This makes it a versatile tool for a wide range of soldering tasks.

- Efficient and Safe: Soldering stations are designed to be more energy-efficient and safer to use compared to basic soldering irons. They often come with features such as automatic shut-off and temperature lock to prevent overheating and potential accidents.

When it comes to choosing a soldering station, there are a few key factors to consider:

- Power: Soldering stations come in a range of power options, typically ranging from 40 watts to 100 watts. The power you need will depend on the type of projects you will be working on.

- Temperature Range: Make sure to choose a soldering station with a temperature range that is suitable for your specific soldering needs. Some stations may have a fixed temperature, while others offer adjustable temperature settings.

- Additional Features: Some soldering stations come with additional features such as digital displays, temperature presets, and sleep modes. Consider which features are important to you and your projects.

- Budget: Soldering stations can range from affordable to high-end, so it’s important to consider your budget when making a purchase. Keep in mind that a good quality soldering station can last for many years, making it a worthwhile investment for serious electronics enthusiasts.

Overall, a soldering station is a must-have tool for anyone working with electronics. Its temperature control, consistent heat, and interchangeable tips make it a versatile and efficient tool for a wide range of soldering tasks. So if you’re serious about electronics, consider investing in a good quality soldering station for your workshop.

3. Soldering Gun

The soldering gun, also known as a soldering iron gun, is a popular tool used for heavy-duty soldering tasks. Its unique pistol-shaped design makes it easy to handle and control, making it a favorite among professionals and hobbyists alike.

One of the main differences between a soldering gun and other types of soldering irons is its larger, copper-based tip. This tip is capable of delivering a higher amount of heat, making it ideal for fast and efficient soldering. The soldering gun is commonly used in automotive, industrial, and heavy electronics applications.

Features of a Soldering Gun

Here are some key features that make the soldering gun stand out from other types of soldering irons:

- Pistol-shaped design: The soldering gun’s unique shape allows for a comfortable grip and easy maneuverability.

- Larger tip: As mentioned earlier, the soldering gun’s tip is larger than other soldering irons, allowing for more heat to be delivered.

- High heat output: The soldering gun can reach temperatures of up to 1000 degrees Fahrenheit, making it suitable for heavy-duty soldering tasks.

- Quick heating time: Due to its high heat output, the soldering gun has a quick heating time, allowing for faster soldering.

- Trigger switch: The trigger switch on the soldering gun allows for easy on and off control, making it convenient to use.

- Replaceable tips: Most soldering guns come with interchangeable tips, allowing for versatility in soldering different types of materials.

Uses of a Soldering Gun

The soldering gun is a versatile tool that can be used for various soldering tasks. Some common uses include:

- Joining heavy-gauge wires: The high heat output of the soldering gun makes it suitable for joining thick wires, such as those used in automotive and industrial applications.

- Soldering metal sheets: The soldering gun’s large tip and high heat make it ideal for soldering metal sheets, such as those used in roofing or plumbing.

- Repairing electronics: The soldering gun can also be used for repairing electronic devices, such as circuit boards or small appliances.

- Creating stained glass: The high heat output of the soldering gun makes it suitable for soldering pieces of stained glass together.

Tips for Using a Soldering Gun

Here are some tips to keep in mind when using a soldering gun:

- Choose the right tip: Make sure to use the appropriate tip for the material you are soldering. A larger tip is better for thicker materials, while a smaller tip is better for delicate work.

- Preheat the tip: It is important to preheat the tip of the soldering gun before use. This ensures that the solder will melt quickly and evenly.

- Keep the tip clean: Regularly clean the tip of the soldering gun to remove any buildup of solder or debris. This will ensure better heat transfer and prevent damage to the tip.

- Use proper safety precautions: As with any soldering tool, it is important to use proper safety precautions, such as wearing protective eyewear and working in a well-ventilated area.

In conclusion, the soldering gun is a powerful and versatile tool that is essential for heavy-duty soldering tasks. Its unique design and high heat output make it a favorite among professionals and hobbyists alike. By following the tips mentioned above, you can ensure safe and efficient use of your soldering gun for all your soldering needs.

Key Considerations for Choosing a Soldering Iron

1. Temperature Control

Temperature control is a crucial factor when selecting a soldering iron for electronics. Different electronic components and solder types require specific temperature settings for optimal soldering results. Soldering irons with adjustable temperature settings provide greater flexibility and compatibility with a wide range of electronic components, ensuring precision and preventing heat damage to sensitive parts.

When it comes to temperature control, there are a few key factors to consider:

- Temperature Range: The temperature range of a soldering iron refers to the lowest and highest temperature it can reach. It is important to choose a soldering iron with a wide temperature range to accommodate different types of solder and electronic components.

- Temperature Stability: A soldering iron with good temperature stability will maintain a consistent temperature throughout the soldering process. This is important for achieving precise and reliable results.

- Temperature Control Method: There are two main types of temperature control methods for soldering irons: manual and digital. Manual temperature control involves adjusting a dial or knob to set the desired temperature, while digital temperature control allows for more precise temperature settings and may include additional features such as temperature presets and temperature lock.

It is also worth noting that some soldering irons may have additional features such as temperature display, temperature calibration, and temperature compensation. These features can be useful for more advanced soldering projects, but may not be necessary for basic electronics soldering.

Overall, the key to temperature control is finding a soldering iron that offers a wide temperature range, good temperature stability, and a temperature control method that suits your needs and preferences.

2. Wattage and Power

When it comes to choosing a soldering iron, one of the key considerations is its wattage and power rating. This determines the heat output and speed of reaching operating temperature, making it an important factor in achieving efficient and effective soldering results.

Here are some important points to keep in mind when considering the wattage and power of a soldering iron:

- Higher wattage irons heat up faster and can handle larger soldering tasks, while lower wattage irons are suitable for delicate electronic work.

- It’s important to match the soldering iron’s wattage to the intended soldering tasks. Using a higher wattage iron for delicate work can lead to overheating and damaging the components.

- On the other hand, using a lower wattage iron for larger tasks can result in longer heat-up times and inefficient soldering.

So how do you determine the right wattage for your soldering iron? Here are some general guidelines:

- For small electronic projects and delicate soldering, a 15-30 watt iron is usually sufficient.

- For medium-sized projects and general use, a 30-50 watt iron is recommended.

- For larger projects and heavy-duty soldering, a 50-80 watt iron is ideal.

It’s also important to note that the wattage of a soldering iron is not the only factor that affects its heat output. The type and quality of the heating element also play a significant role. A high-quality heating element can provide more efficient heat transfer, resulting in better soldering performance even with a lower wattage iron.

Another important consideration is the power source of the soldering iron. Most soldering irons are powered by electricity, but there are also battery-powered and butane-powered options available. Battery-powered irons are more portable and convenient, but they may have lower wattage and shorter battery life. Butane-powered irons, on the other hand, offer more power and longer run time, but they can be more expensive and require refilling of butane fuel.

When it comes to power, it’s also important to consider the voltage and frequency of the soldering iron. Most soldering irons operate on 110-120 volts and 60 Hz frequency, but there are also models that can handle 220-240 volts and 50 Hz frequency. Make sure to check the voltage and frequency compatibility of the soldering iron with your power source before purchasing.

In conclusion, the wattage and power rating of a soldering iron are important factors to consider when choosing the right tool for your soldering needs. Make sure to match the wattage to your intended tasks and consider the type and quality of the heating element, power source, and voltage and frequency compatibility for optimal soldering performance.

3. Heat-up Time

The heat-up time of a soldering iron is an essential consideration for efficiency and productivity. Soldering irons with rapid heat-up times reduce waiting periods and allow users to begin soldering quickly, making them ideal for time-sensitive projects and production environments.

When it comes to heat-up time, there are a few key factors to consider:

- Power and Wattage: The power and wattage of a soldering iron can greatly affect its heat-up time. Generally, the higher the wattage, the faster the iron will heat up. However, it’s important to note that higher wattage irons may also require more power and can be more expensive.

- Type of Heating Element: The type of heating element used in a soldering iron can also impact its heat-up time. Ceramic heating elements tend to heat up faster than other types, such as nickel-chromium or copper.

- Temperature Control: Having temperature control on your soldering iron can also affect its heat-up time. With temperature control, you can set the desired temperature and the iron will heat up to that specific temperature, reducing the time it takes to reach the desired heat level.

Aside from these factors, there are also some tips and tricks you can use to decrease heat-up time and increase efficiency:

- Preheating: Preheating your soldering iron before use can significantly reduce heat-up time. Simply turn on the iron a few minutes before you plan to use it, and it will be ready to go when you are.

- Cleaning and Maintenance: Keeping your soldering iron clean and well-maintained can also help with heat-up time. A dirty or damaged iron may take longer to heat up, so be sure to regularly clean and replace any worn out parts.

- Choosing the Right Tip: The type of tip you use on your soldering iron can also affect its heat-up time. Thinner tips tend to heat up faster, while thicker tips may take longer. Consider the type of project you will be working on and choose a tip that will heat up quickly and efficiently.

Ultimately, the heat-up time of a soldering iron will depend on a variety of factors, including the type of iron, its wattage, and how well it is maintained. By considering these factors and implementing some tips and tricks, you can ensure that your soldering iron heats up quickly and efficiently, allowing you to get to work faster and complete projects in a timely manner.

4. Soldering Iron Tips and Compatibility

The selection of soldering iron tips and their compatibility with the soldering iron is critical for achieving precise and clean soldering joints. Different tip shapes and sizes cater to specific soldering requirements, such as surface mount technology (SMT), through-hole components, and fine-pitch soldering. Ensuring compatibility with a variety of tips enhances the versatility of the soldering iron for different electronics applications.

When it comes to soldering, the tip of the soldering iron is the most important part. It is the point of contact between the iron and the solder, and it is responsible for transferring heat to the joint. Therefore, choosing the right tip and ensuring compatibility with your soldering iron is crucial for successful soldering.

There are various types of soldering iron tips available in the market, each designed for specific soldering tasks. Some common types include:

- Chisel Tip: This is the most commonly used tip and is suitable for general soldering tasks. It has a flat surface with a pointed end, making it ideal for soldering larger components and through-hole joints.

- Conical Tip: This tip has a pointed end, making it suitable for precision soldering tasks such as surface mount technology (SMT) and fine-pitch soldering.

- Bevel Tip: This tip has a sloped edge, making it ideal for soldering in tight spaces and hard-to-reach areas.

- Hakko Tip: This is a specialized tip designed for Hakko soldering irons. It has a unique shape that allows for better heat transfer and is suitable for a wide range of soldering tasks.

When selecting soldering iron tips, there are a few factors to keep in mind to ensure compatibility and optimal performance:

- Tip Size: The size of the tip is an important consideration as it determines the amount of heat transferred to the joint. A larger tip is suitable for larger components and through-hole joints, while a smaller tip is better for precision soldering tasks.

- Tip Shape: As mentioned earlier, different tip shapes cater to different soldering tasks. It is important to choose the right shape for the job to ensure clean and precise soldering joints.

- Tip Coating: Some tips come with a special coating, such as iron-plated or chrome-plated, to prevent oxidation and improve heat transfer. These tips are more durable and provide better performance compared to uncoated tips.

- Tip Material: Soldering iron tips are typically made of copper, which is a good conductor of heat. However, some tips may have an iron or nickel core for added durability and heat resistance.

Not all soldering iron tips are compatible with every soldering iron. It is important to check the compatibility of the tip with your soldering iron before purchasing. Some tips are designed for specific soldering iron brands, while others are more universal and can fit a variety of irons.

Additionally, some soldering irons have interchangeable tips, allowing you to switch between different tip sizes and shapes for different soldering tasks. This adds to the versatility of the soldering iron and makes it suitable for a wider range of applications.

To ensure the longevity and optimal performance of your soldering iron tips, it is important to take proper care of them. Here are some tips for maintaining your soldering iron tips:

- Keep the tip clean and free of any debris or solder residue.

- Use a damp sponge or brass wool to clean the tip while it is hot.

- Avoid using abrasive materials to clean the tip as it can damage the coating.

- Tin the tip with solder after each use to prevent oxidation.

- Replace the tip when it becomes worn out or damaged.

By following these tips, you can ensure that your soldering iron tips last longer and provide optimal performance for all your soldering needs.

Choosing the right soldering iron tip and ensuring compatibility with your soldering iron is crucial for successful soldering. Consider the type, size, shape, coating, and material of the tip, as well as its compatibility with your soldering iron. Proper maintenance of the tip is also important for optimal performance. By keeping these factors in mind, you can achieve precise and clean soldering joints for a variety of electronics applications.

Best Practices for Soldering Electronics

1. Safety Precautions

When soldering electronics, it’s important to observe safety precautions to protect yourself and the electronic components. This includes working in a well-ventilated area, using appropriate protective gear such as safety glasses and heat-resistant gloves, and being mindful of the hot soldering iron tip to prevent burns and injuries.

Here are some additional safety precautions to keep in mind when soldering:

- Always unplug the soldering iron when not in use to prevent accidental burns or fires.

- Do not touch the soldering iron tip with your bare hands, even when it is not plugged in. The tip can remain hot for a few minutes after use.

- Keep flammable materials, such as paper or fabric, away from your work area to prevent fires.

- Do not eat or drink while soldering to avoid ingesting any harmful fumes.

- Make sure your work area is well-lit to avoid eye strain and potential accidents.

- Keep a fire extinguisher nearby in case of emergencies.

It’s also important to be aware of the potential hazards of the materials you are working with. Lead-based solder, for example, can release toxic fumes when heated. If you are using lead-based solder, make sure to work in a well-ventilated area and wash your hands thoroughly after soldering.

Additionally, it’s important to properly dispose of any waste materials, such as used solder or flux, to avoid environmental contamination.

By following these safety precautions, you can ensure a safe and successful soldering experience.

2. Proper Soldering Techniques

2. Proper Soldering Techniques

Soldering is a crucial skill for anyone working with electronics. It involves joining two metal components together using a heated soldering iron and a metal alloy called solder. Adhering to proper soldering techniques ensures high-quality and reliable solder connections, which are essential for the functionality and longevity of electronic devices.

Here are some key techniques to keep in mind when soldering:

- Clean the soldering iron tip: Before starting any soldering project, it is important to clean the tip of your soldering iron. This helps to remove any built-up residue or oxidation that can affect the quality of your solder joints. You can use a damp sponge or a specialized tip cleaner to clean the tip.

- Tin the tip: Tinning the tip of your soldering iron involves coating it with a thin layer of solder. This helps to improve heat transfer and prevents oxidation. To tin the tip, simply melt a small amount of solder onto the tip and wipe off any excess with a damp sponge.

- Apply the right amount of solder: Too much or too little solder can result in weak or unreliable connections. The general rule of thumb is to use the smallest amount of solder necessary to create a strong bond. This will vary depending on the size of the components being soldered.

- Properly heat both the component and the solder: To create a strong and durable bond, both the component and the solder need to be heated to the correct temperature. This ensures that the solder flows evenly and creates a solid connection. If the solder is not heated enough, it may not bond properly, and if it is overheated, it can cause damage to the component.

Here are some additional tips to keep in mind when soldering:

- Use the right soldering iron: The type and wattage of your soldering iron will depend on the size and complexity of your project. A small, low-wattage iron is suitable for delicate electronics, while a larger, high-wattage iron is better for larger components and thicker wires.

- Use the right type of solder: There are different types of solder available, such as lead-based and lead-free. It is important to use the right type of solder for your project to ensure a strong and reliable connection.

- Keep your work area clean: A clean work area is essential for successful soldering. Make sure to remove any debris or dust from your work surface to prevent it from getting into your solder joints.

- Practice makes perfect: Soldering is a skill that takes time and practice to master. Don’t be discouraged if your first few attempts are not perfect. With practice, you will develop a steady hand and be able to create clean and precise solder joints.

By following these proper soldering techniques, you can ensure high-quality and reliable connections in your electronic projects. Remember to always prioritize safety and take your time to create clean and precise solder joints. Happy soldering!

3. Cleaning and Maintenance

Regular cleaning and maintenance of the soldering iron are essential for its longevity and consistent performance. This involves removing oxidation from the soldering iron tip, ensuring a clean and tinned tip surface, and keeping the soldering iron in good working condition to prevent soldering defects and issues.

To ensure your soldering iron stays in top condition, here are some tips for cleaning and maintenance:

- Always unplug the soldering iron before cleaning or performing maintenance.

- Use a damp sponge or cloth to wipe the tip of the soldering iron after each use. This will remove any excess solder and help prevent oxidation.

- If the tip of your soldering iron becomes heavily oxidized, use a brass wire brush or a tip cleaner to remove the oxidation. Be sure to re-tin the tip afterwards.

- Regularly check the tip of your soldering iron for any signs of damage or wear. If the tip is damaged, replace it immediately to ensure proper soldering.

- Keep the soldering iron in a clean and dry place when not in use. This will prevent dust and debris from accumulating on the tip.

- Inspect the power cord and plug of your soldering iron for any damage or fraying. If there is any damage, replace the cord before using the soldering iron again.

- For soldering irons with adjustable temperature settings, make sure to calibrate the temperature regularly to ensure accurate readings.

In addition to regular cleaning, there are some maintenance tasks that should be performed on a less frequent basis:

- Replace the soldering iron tip when it becomes worn or damaged. This will ensure proper heat transfer and prevent soldering defects.

- Check the heating element of your soldering iron for any signs of damage or wear. If there are any issues, replace the heating element to maintain consistent performance.

- For soldering irons with replaceable filters, make sure to replace them regularly to prevent clogs and maintain proper airflow.

By following these cleaning and maintenance tips, you can ensure that your soldering iron stays in top condition and provides consistent and reliable performance for all your electronics projects.

Common Mistakes to Avoid When Soldering Electronics

Soldering is a crucial skill for anyone working with electronics. It involves joining two metal components together using a filler metal, known as solder, to create a strong and conductive connection. However, even the most experienced solderers can make mistakes that can lead to faulty connections and damage to electronic components. To ensure the integrity of your soldered connections, it’s important to be aware of these common mistakes and how to avoid them.

One of the most common mistakes when soldering electronics is overheating components. This can happen when the soldering iron is set to a high temperature or when it is left on a component for too long. Overheating can cause damage to sensitive electronic components, such as transistors and diodes, and can also lead to the solder melting and creating a short circuit.

To avoid this mistake, it’s important to use a soldering iron with temperature control and to set it to the appropriate temperature for the components you are working with. It’s also important to work quickly and efficiently, moving the iron away from the component as soon as the solder has melted.

Another common mistake is using too much solder. While it may seem like more solder will create a stronger connection, it can actually have the opposite effect. Excessive solder can create a messy and uneven joint, making it difficult for the solder to flow and bond properly. This can result in a weak connection that is prone to breaking or failing.

To avoid this mistake, use only the amount of solder needed to create a strong and neat joint. It’s also important to use the correct type of solder for the job, as some solders are more prone to creating excessive amounts of flux, which can also lead to a weak connection.

Flux is a chemical compound that helps to remove oxidation and impurities from the metal surfaces being soldered, allowing the solder to flow and bond properly. Insufficient flux application is a common mistake that can result in a weak and unreliable connection. Without enough flux, the solder may not bond properly, leading to a joint that is prone to breaking or failing.

To avoid this mistake, make sure to apply enough flux to the joint before soldering. It’s also important to use a flux that is appropriate for the type of solder you are using.

Proper soldering techniques are crucial for creating strong and reliable connections. However, many beginners make the mistake of using improper techniques, such as not heating the joint enough or not holding the soldering iron at the correct angle. This can result in a weak and unreliable joint that is prone to breaking or failing.

To avoid this mistake, it’s important to learn and practice proper soldering techniques. This includes heating the joint evenly, using the correct amount of solder, and holding the soldering iron at the correct angle.

Another common mistake is not properly cleaning and maintaining your soldering iron. Over time, flux and other debris can build up on the tip of the iron, making it difficult for the solder to flow and bond properly. This can result in weak and unreliable connections.

To avoid this mistake, it’s important to regularly clean your soldering iron tip with a damp sponge or brass wire cleaner. It’s also important to regularly replace the tip when it becomes worn or damaged.

- Overheating components can lead to damage and short circuits.

- Using excessive solder can create messy and weak joints.

- Insufficient flux application can result in weak and unreliable connections.

- Improper soldering techniques can lead to weak and unreliable joints.

- Regularly cleaning and maintaining your soldering iron is crucial for creating strong connections.

By being aware of these common mistakes and taking the necessary precautions, you can ensure the integrity of your soldered connections and avoid costly mistakes. Remember to always use the appropriate tools and techniques for the job, and to regularly clean and maintain your soldering iron for optimal performance.

Comparative Analysis of Top Soldering Irons for Electronics

1. Weller WE1010

The Weller WE1010 soldering iron is a top-of-the-line tool for professional electronics work. It offers precise temperature control, rapid heat-up time, and compatibility with a diverse range of soldering tips. This makes it a versatile and reliable choice for a variety of soldering applications.

The Weller WE1010 features a digital display that allows for precise temperature control. This is essential for electronics work, as different components and materials require different temperatures for soldering. The temperature can be adjusted in increments of 1 degree, allowing for precise and accurate adjustments.

In addition, the WE1010 has a temperature range of 200-850 degrees Fahrenheit, making it suitable for a wide range of soldering tasks. This temperature range is also ideal for working with both lead-based and lead-free solder, providing flexibility for different projects.

The WE1010 has a rapid heat-up time, reaching its maximum temperature in just 40 seconds. This is significantly faster than many other soldering irons on the market, allowing for quick and efficient work. This is especially beneficial for professionals who may have tight deadlines or a high volume of work.

The Weller WE1010 is compatible with a wide range of soldering tips, making it a versatile tool for different soldering tasks. It is compatible with the Weller ET series tips, as well as the PT series tips with the use of an adapter. This allows for customization and flexibility in choosing the right tip for the job.

- The WE1010 has a sleep mode function, which automatically reduces the temperature when the iron is not in use for a set period of time. This helps to prolong the life of the tip and conserve energy.

- It also has a standby mode, which maintains a lower temperature when the iron is not in use but still plugged in. This allows for quick and easy reactivation when needed.

- The iron has a lightweight and ergonomic design, making it comfortable to use for extended periods of time.

- It also comes with a safety rest, which holds the iron securely when not in use.

Overall, the Weller WE1010 is a high-quality soldering iron that offers precise temperature control, rapid heat-up time, and compatibility with a diverse range of tips. Its additional features make it a convenient and efficient tool for professional electronics work. It is a top choice for those looking for a reliable and versatile soldering iron.

2. Hakko FX888D

The Hakko FX888D soldering iron is a top-of-the-line tool that is highly regarded by electronics enthusiasts and professionals alike. It offers superior heat recovery, temperature stability, and ergonomic design, making it a top choice for any soldering project.

- Extensive range of soldering temperatures, from 120°C to 899°C, allowing for versatility in various soldering tasks.

- User-friendly controls, including a digital display and adjustable temperature control, making it easy to use for beginners and experts alike.

- Quick heat-up and recovery time, ensuring efficient and uninterrupted soldering sessions.

- Temperature stability within ±1°C, providing precise and consistent results.

- Ergonomic design with a comfortable grip, reducing hand fatigue during extended use.

- Compact and lightweight, making it portable and easy to store.

- Efficient and reliable soldering: The Hakko FX888D’s quick heat-up and recovery time, along with its temperature stability, ensures efficient and consistent results for any soldering project.

- Easy to use: With user-friendly controls and a digital display, this soldering iron is suitable for both beginners and experienced users.

- Comfortable and ergonomic: The ergonomic design and comfortable grip of the Hakko FX888D make it easy to use for extended periods without causing hand fatigue.

- Portable and compact: This soldering iron is lightweight and compact, making it easy to transport and store.

The Hakko FX888D comes with a variety of accessories to enhance your soldering experience:

- Tip cleaning wire: This helps to keep your soldering tip clean and free of debris, ensuring optimal performance.

- Soldering iron stand: The stand provides a safe and stable place to rest the soldering iron when not in use.

- Soldering iron holder: This holder keeps the soldering iron securely in place during use, preventing accidents and damage to your work area.

- Soldering iron tip: The Hakko FX888D comes with a high-quality soldering iron tip, but it is also compatible with a variety of other tips for different soldering tasks.

The Hakko FX888D is a top choice for anyone in need of a reliable and efficient soldering iron. Its superior heat recovery, temperature stability, and ergonomic design make it a valuable tool for any soldering project. With its user-friendly controls and accessories, it is suitable for both beginners and professionals. Invest in the Hakko FX888D and take your soldering skills to the next level.

3. X-Tronic Model 3020-XTS

The X-Tronic Model 3020-XTS soldering iron is a top-of-the-line tool that offers advanced features for precision soldering and intricate electronic work. It stands out among other soldering irons for its versatility, performance, and user-friendly design.

Adjustable Temperature

One of the key features of the X-Tronic Model 3020-XTS is its adjustable temperature control. This allows you to set the temperature to the exact degree needed for your specific soldering project. The temperature range is from 392°F to 896°F, giving you the flexibility to work with a variety of materials and soldering techniques.

The temperature is displayed on a digital screen, making it easy to read and monitor while you work. This eliminates the need for guesswork and ensures consistent and accurate results every time.

Digital Display

The digital display on the X-Tronic Model 3020-XTS is not only used for temperature control, but also for other important features. It has a built-in sleep function that can be set to automatically turn off the iron after a certain amount of time, helping to conserve energy and prevent accidents.

The display also shows the iron’s current voltage, which can be adjusted from 110V to 120V. This is useful for international users or for those who need to work with different voltage requirements.

Soldering Accessories

The X-Tronic Model 3020-XTS comes with a variety of accessories that make it a complete soldering kit. These include multiple soldering tips, a cleaning sponge, a soldering iron stand, and a solder roll holder. The different tips allow you to customize your soldering experience for different projects, while the stand and holder keep your work area organized and safe.

Additional Features

In addition to its main features, the X-Tronic Model 3020-XTS has several other useful functions. It has a built-in temperature calibration feature, which ensures that the iron is always working at the correct temperature. It also has a temperature lock function, which prevents accidental temperature changes while you work.

The iron’s handle is made of heat-resistant material, making it comfortable to hold and reducing the risk of burns. It also has a compact and lightweight design, making it easy to use for extended periods of time without causing strain on your hand or wrist.

Conclusion

The X-Tronic Model 3020-XTS is a top choice for anyone looking for a high-quality soldering iron. Its advanced features, including adjustable temperature, digital display, and a variety of accessories, make it a versatile and reliable tool for precision soldering and electronic work. With its user-friendly design and additional functions, it is a must-have for any electronics enthusiast or professional.

- Adjustable temperature range from 392°F to 896°F

- Digital display for temperature control and other features

- Comes with multiple soldering tips, cleaning sponge, stand, and holder

- Built-in temperature calibration and lock functions

- Heat-resistant handle and compact design for comfortable use

How to Find the Best Soldering Iron for Electronics

When it comes to soldering electronics, having the right tools is crucial for achieving professional results. One of the most important tools for this task is the soldering iron. However, with so many options available in the market, it can be overwhelming to choose the best soldering iron for your specific needs. In this section, we will discuss the key factors to consider when searching for the best soldering iron for electronics.

Before diving into the key considerations, it’s important to understand the different types of soldering irons available. The three main types are soldering pencil, soldering station, and soldering gun.

- Soldering Pencil: This is the most common type of soldering iron used for electronics. It is lightweight, easy to handle, and allows for precise control over the temperature and tip.

- Soldering Station: A soldering station consists of a base unit and a detachable soldering iron. It offers more advanced features such as adjustable temperature control, digital displays, and interchangeable tips.

- Soldering Gun: This type of soldering iron is typically used for heavy-duty soldering tasks. It has a larger and more powerful heating element, making it suitable for larger electronic components or thicker wires.

When selecting a soldering iron for electronics, there are several factors to keep in mind to ensure you get the best tool for your specific needs.

- Temperature Control: The ability to control the temperature of the soldering iron is crucial for achieving precise and consistent results. Look for a soldering iron with adjustable temperature settings or a digital display for accurate temperature readings.

- Wattage and Power: The wattage of a soldering iron determines how quickly it can heat up and maintain a stable temperature. For electronics soldering, a wattage of 40-60 watts is typically sufficient.

- Heat-up Time: The heat-up time of a soldering iron can vary depending on its wattage and heating element. Look for a soldering iron with a fast heat-up time to save time and increase efficiency.

- Soldering Iron Tips and Compatibility: The tip of a soldering iron is responsible for transferring heat to the solder and the component being soldered. It’s important to choose a soldering iron with interchangeable tips to accommodate different types of soldering tasks and components.

To ensure successful and safe soldering, it’s important to follow some best practices when using a soldering iron for electronics.

- Safety Precautions: Soldering involves working with high temperatures and potentially hazardous materials. Always wear protective gear such as safety glasses and gloves to protect yourself from burns and fumes.

- Proper Soldering Techniques: It’s essential to use the correct techniques when soldering electronics to avoid damaging the components or creating weak connections. Some key techniques include tinning the tip, using the right amount of solder, and avoiding excessive heat.

- Cleaning and Maintenance: Regularly cleaning and maintaining your soldering iron is crucial for its longevity and performance. Make sure to clean the tip after each use and replace it when it becomes worn out.

Even with the best tools and techniques, mistakes can still happen when soldering electronics. Here are some common mistakes to avoid to ensure successful soldering:

- Using too much or too little solder

- Not properly heating the components before soldering

- Using the wrong type of solder for the job

- Not cleaning the tip before and after use

To help you make an informed decision, here is a comparative analysis of some of the top soldering irons for electronics:

- Weller WE1010: This soldering station offers adjustable temperature control, fast heat-up time, and interchangeable tips. It is a popular choice among professionals and hobbyists alike.

- Hakko FX888D: This soldering station also features adjustable temperature control, a digital display, and interchangeable tips. It is known for its durability and precision.

- X-Tronic Model 3020-XTS: This soldering station offers a wide range of temperature control, a digital display, and interchangeable tips. It is a budget-friendly option without compromising on quality.

In conclusion, finding the best soldering iron for electronics requires careful consideration of factors such as temperature control, wattage, heat-up time, and tip compatibility. By following best practices and avoiding common mistakes, you can achieve professional results with any of the top soldering irons available in the market. Remember to always prioritize safety and proper maintenance to ensure the longevity and performance of your soldering iron.

Conclusion

In conclusion, selecting the best soldering iron for electronics involves understanding the types of soldering irons available, evaluating key considerations such as temperature control, wattage, and heat-up time, and adopting best practices for safe and effective soldering. Avoiding common soldering mistakes and conducting a comparative analysis of top soldering irons enables the identification of the most suitable soldering iron for electronic applications. With the knowledge gained from this comprehensive guide, individuals can confidently choose the best soldering iron to achieve precise, reliable, and professional-quality soldering results in electronics projects and repairs.