Exploring the Versatility of Butane Soldering Irons

Introduction

A butane soldering iron is a versatile tool that utilizes butane gas to generate heat for soldering, heating, and even light-duty welding. It is a portable and convenient alternative to traditional electric soldering irons, offering cordless operation and the ability to be used in various environments.

In this comprehensive guide, we will delve into the various aspects of butane soldering irons, including their types, benefits, safety measures, and tips for effective usage.

What is a Butane Soldering Iron?

A butane soldering iron is a compact and portable device that employs butane as a fuel source to generate heat for various applications. It consists of a butane reservoir, a heating element, and a tip or nozzle for conducting heat to the workpiece.

This tool is renowned for its cordless operation, making it suitable for outdoor projects, electronics repair, and other soldering tasks. The versatility and convenience of butane soldering irons make them an essential tool for DIY enthusiasts, technicians, and hobbyists.

Benefits of Butane Soldering Irons

Butane soldering irons offer several distinct advantages over conventional electric soldering irons. Their cordless design allows for unrestricted movement and usage in remote or inaccessible locations. Additionally, they heat up rapidly, enabling quick task completion.

The butane fuel source provides a reliable power supply, eliminating the need for electrical outlets, making these irons ideal for on-the-go applications. Furthermore, the ability to adjust the flame or heat output adds to the versatility of butane soldering irons, making them adaptable for different soldering requirements.

Types of Butane Soldering Irons

When it comes to butane soldering irons, there is a wide range of types available, each tailored to specific applications and user preferences. Let’s explore the various types in more detail:

- Built-In Ignition Systems: Some butane soldering irons feature built-in ignition systems, providing the convenience of one-click operation for immediate use. This feature eliminates the need for separate ignition tools and ensures quick and effortless ignition.

- Adjustable Temperature Controls: Certain models are equipped with adjustable temperature controls, allowing users to fine-tune the heat output according to the specific requirements of the task at hand. This versatility enables precise control over the soldering process, catering to a wide range of materials and applications.

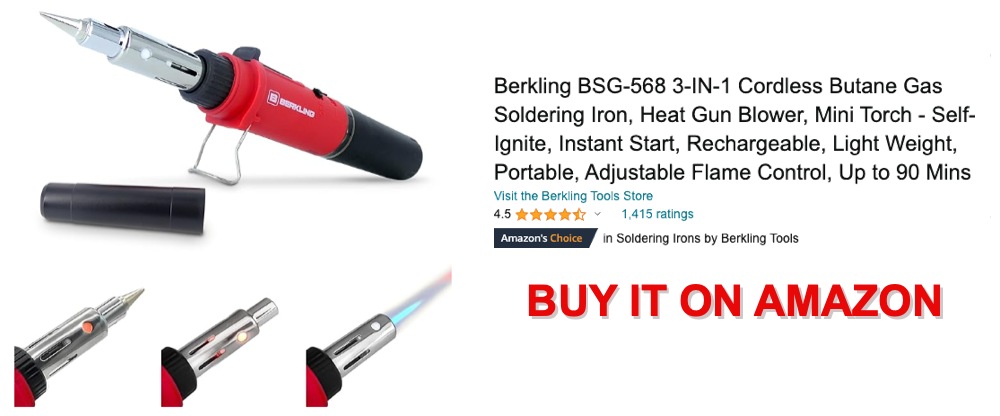

- Multi-Function Capabilities: For more advanced needs, multi-function butane soldering irons offer additional features such as hot air blowers, versatile soldering tips, and even mini torches. These versatile tools are ideal for intricate tasks that demand a variety of soldering techniques and heat applications.

Understanding the nuances of these different types of butane soldering irons is essential for users to make an informed decision and select the most suitable tool for their specific needs.

Whether it’s the simplicity of one-click operation, the precision of adjustable temperature controls, or the versatility of multi-function capabilities, there is a butane soldering iron for every application.

Types of Soldering Tips Ideal for Butane Soldering Irons

Choosing the right soldering tip is crucial for achieving optimal results with your butane soldering iron. Here are some of the most common types of soldering tips and their ideal applications:

- Conical Tips: Conical tips have a pointed end, making them perfect for precision work such as soldering small components on circuit boards. Their fine point allows for precise control and detailed work.

- Chisel Tips: Chisel tips are flat and wide, making them ideal for soldering larger components or applying solder to broad areas. They are great for tasks that require more heat and coverage.

- Knife Tips: Knife tips are similar to chisel tips but with a sharper edge. They are useful for cutting through materials or creating precise lines and shapes in the solder.

- Hot Air Tips: Hot air tips are used in multi-purpose butane soldering irons for applications like heat shrinking and desoldering. They blow hot air rather than directly applying heat through a tip, making them versatile for various tasks.

| Soldering Tip Type | Suitable Application | Recommended Wattage |

|---|---|---|

| Conical Tip | Precision work such as soldering small components on circuit boards. | 15-30W |

| Chisel Tip | Soldering larger components or applying solder to broad areas. | 40-60W |

| Knife Tip | Cutting through materials or creating precise lines and shapes in the solder. | 40-60W |

| Hot Air Tip | Heat shrinking, desoldering, and applications requiring hot air. | Varies with use, typically 50-100W |

Best Applications for Butane Soldering Irons

Butane soldering irons are incredibly versatile tools suitable for a wide range of applications. Here are some of the best uses for both single-purpose and multi-purpose models:

- Electronics Repair: Butane soldering irons are perfect for repairing electronic devices. Their portability allows for on-site repairs, and the precision tips are ideal for soldering small components on circuit boards.

- Jewelry Making: For intricate jewelry work, a butane soldering iron provides the fine control needed to solder tiny pieces without damaging delicate materials. The quick heat-up time is a bonus for efficient workflow.

- Automotive Repairs: In automotive repair, the ability to work in confined spaces without needing a power outlet makes butane soldering irons invaluable. They are used for wiring repairs, heat shrinking, and even small welding tasks.

- Plumbing: For small-scale plumbing tasks, such as fixing leaks in metal pipes, a butane soldering iron can be used for light-duty welding and soldering. The multi-purpose models with hot air tips can also help in drying and heat-shrinking applications.

- Crafting and DIY Projects: DIY enthusiasts will find butane soldering irons handy for a variety of crafting projects. Whether it’s creating stained glass art, building models, or repairing household items, the flexibility and portability of these tools make them a great choice.

- Multi-Purpose Applications: Multi-purpose butane soldering irons shine in scenarios where versatility is key. They can be used for soldering, cutting, shaping, heat shrinking, and more, making them ideal for professionals who need one tool for multiple tasks. The combination of different tips and functions allows for a seamless transition between different types of work, enhancing efficiency and productivity.

Choosing the Right Butane Gas for Your Butane Soldering Iron

When it comes to choosing the right butane gas for your soldering iron, it’s important to consider a few key factors to ensure optimal performance and safety. The type of butane gas you select can have a significant impact on the efficiency and longevity of your soldering iron, so it’s essential to make an informed decision.

Here are some important factors to keep in mind when selecting the right butane gas for your soldering iron:

- Purity: Look for high-purity butane gas to minimize the risk of clogging and impurities that can affect the performance of your soldering iron.

- Pressure: Consider the pressure of the butane gas, as it can impact the temperature and flame consistency of your soldering iron.

- Compatibility: Ensure that the butane gas you choose is compatible with your specific soldering iron model to prevent damage and ensure proper functioning.

- Filtration: Check if the butane gas is filtered to remove any potential contaminants that could compromise the integrity of your soldering iron.

There are various types of butane gas available in the market, each with its own unique characteristics and applications. Some common types of butane gas include:

- Standard Butane: Widely used for general soldering purposes and compatible with most soldering iron models. [ Recommendation: Zippo Pure Butane refill ]

- Triple-Refined Butane: Known for its high level of purity and minimal impurities, making it ideal for delicate electronic soldering. [Recommendation: King Butane Fuel Triple Refined ]

- Colibri Premium Butane: A popular choice for professional soldering applications, offering exceptional purity and performance.

Proper storage and handling of butane gas are essential to maintain its quality and safety. Consider the following best practices:

- Store butane gas in a cool, dry place away from direct sunlight and heat sources.

- Keep butane canisters upright to prevent leakage and ensure proper functioning.

- Check for any damage or corrosion on the canister before use, and discard if any issues are found.

- Handle butane gas with care to prevent exposure to skin and eyes, and avoid inhaling the gas.

By considering these factors and best practices, you can confidently choose the right butane gas for your soldering iron, ensuring reliable performance and safety for your soldering projects.

Safety Measures for Butane Soldering Irons

- Operate the butane soldering iron in a well-ventilated area to prevent the accumulation of combustible gases.

- Allow the soldering iron to cool down completely before refueling to avoid the risk of fuel leakage and combustion.

- Use appropriate protective gear, such as heat-resistant gloves and safety goggles, to safeguard against potential burns and eye injuries.

- Inspect the soldering iron for any signs of damage before each use, including the fuel tank, ignition system, and soldering tip.

- Store the butane soldering iron in a safe and secure location, away from flammable materials and out of reach of children.

Tips and Techniques for Using Butane Soldering Irons

Mastering effective usage of butane soldering irons involves implementing certain tips and techniques to optimize performance and achieve precise results. Prior to soldering, ensure that the work area is clean and free of flammable materials to minimize fire hazards.

When igniting the soldering iron, hold it away from the body and flammable objects to prevent accidental injuries or damage. Additionally, practice regulating the flame intensity to suit the soldering task, and allow the tool to cool down adequately after usage. These practical tips enhance safety and usability, enabling users to carry out soldering tasks with proficiency and confidence.

Essential Maintenance Tips for Your Butane Soldering Iron

Proper maintenance of your butane soldering iron is crucial for ensuring its longevity and optimal performance. Here are some essential maintenance tips to keep your butane soldering iron in top condition:

- Clean the Soldering Tip Regularly: Use a brass wire sponge or damp sponge to clean the soldering tip regularly. This helps to remove any excess solder and oxidation, ensuring a clean and effective tip.

- Inspect the Ignition System: Regularly check the ignition system of your butane soldering iron to ensure it is functioning properly. Look for any signs of wear or damage, and replace any faulty components as needed.

- Check Gas Levels: Monitor the butane gas levels in your soldering iron and refill it as necessary. Keeping the butane reservoir adequately filled is essential for consistent heat and performance.

- Store Properly: When not in use, store your butane soldering iron in a dry and safe location. Protect it from dust and moisture to prevent any damage.

- Inspect for Leaks: Regularly inspect your soldering iron for any gas leaks. This can be done by applying a soapy solution to the connections and checking for bubbles, indicating a leak.

Conclusion

In conclusion, butane soldering irons represent a versatile and convenient solution for soldering, heating, and light-duty welding tasks. Their portability, rapid heating, and cordless operation make them indispensable tools for various applications.

By understanding the different types, benefits, and safety measures associated with butane soldering irons, users can make informed decisions and utilize these tools effectively. Implementing the recommended tips and techniques further enhances the usability and safety of butane soldering irons, ensuring proficient and secure operation.