Are the fumes from soldering toxic?

Introduction

Soldering is a common practice in electronics manufacturing, plumbing, and various DIY projects. While it is a useful technique, there are potential health risks associated with the fumes produced during soldering. In this article, we will delve into the composition of soldering fumes, exposure risks, health effects, safety measures, regulations, and safety guidelines to provide comprehensive insights into the health risks of soldering fumes.

Answer to the Question

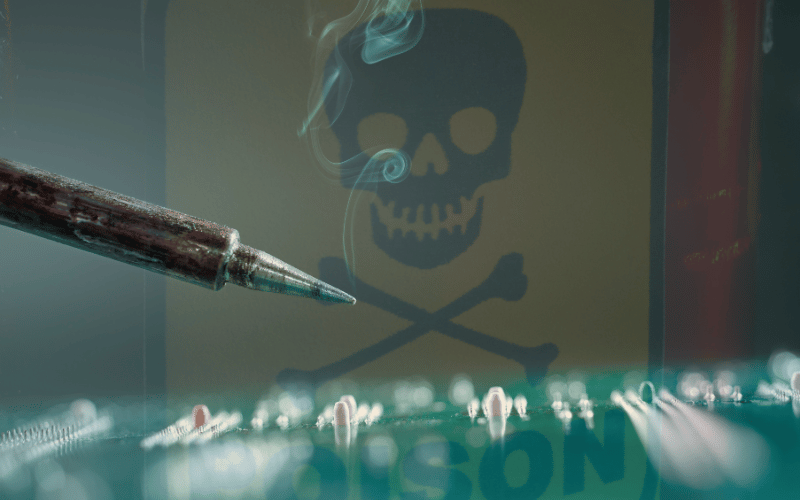

Yes, the fumes from soldering can be toxic.

Health Risks of Soldering Fumes

1. Composition of Soldering Fumes

Soldering fumes consist of a complex mixture of airborne particles and gases that result from the heating of solder and flux. The composition includes volatile organic compounds (VOCs), metal fumes, and flux residues. VOCs such as benzene and toluene are known to have adverse health effects, while metal fumes can lead to respiratory issues. The presence of rosin-based flux adds to the harmful nature of soldering fumes, making it crucial to understand their composition to mitigate associated health risks.

2. Exposure Risks

Individuals working with soldering equipment are at risk of exposure to harmful fumes and gases. Whether in professional settings or home workshops, prolonged exposure to soldering fumes can result in various health issues. Factors such as inadequate ventilation, improper soldering practices, and lack of personal protective equipment contribute to increased exposure risks. Understanding the potential hazards associated with exposure to soldering fumes is vital for creating a safe working environment.

3. Health Effects

Exposure to soldering fumes can have significant implications for the health of individuals involved in soldering activities. The following health effects may arise from exposure to soldering fumes:

- Respiratory Irritation: Inhalation of soldering fumes can lead to respiratory irritation, causing discomfort and breathing difficulties.

- Dizziness: Prolonged exposure to soldering fumes may result in dizziness and lightheadedness.

- Headaches: Individuals exposed to soldering fumes may experience frequent headaches as a result of the exposure.

- Occupational Asthma: The rosin found in flux can cause occupational asthma, leading to significant breathing difficulties and long-term health implications.

- Long-term Lung Damage: In severe cases, continuous exposure to soldering fumes can result in long-term lung damage, impacting the overall respiratory health of individuals.

- Lead Poisoning: The presence of lead in certain solders poses a significant health risk, especially when inhaled or ingested. Lead poisoning can lead to a range of health issues, necessitating proactive risk management and protective measures.

Recognizing the potential health effects of soldering fumes is essential for proactive risk management and safeguarding the well-being of individuals involved in soldering activities. Implementing safety measures and adhering to proper ventilation and equipment usage guidelines are critical in mitigating these health risks.

4. Safety Measures

Implementing effective safety measures is imperative to mitigate the health risks associated with soldering fumes. Adequate ventilation systems, such as fume extractors and local exhaust ventilation, help minimize exposure to harmful fumes. Personal protective equipment, including respiratory masks and safety goggles, offers crucial protection for individuals working in environments where soldering takes place. Adhering to proper soldering practices, such as avoiding overheating and using lead-free solder when possible, contributes to creating a safer soldering work environment.

- Effective Ventilation Systems

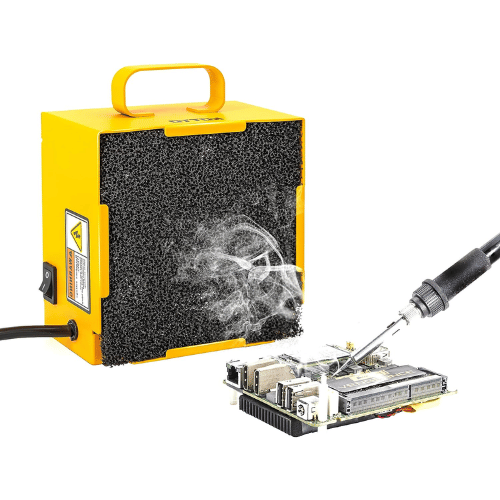

- Implementing effective ventilation systems is crucial for maintaining a safe working environment when soldering. Fume extractors and local exhaust ventilation are essential in reducing exposure to harmful fumes. By ensuring adequate ventilation, the risk of inhaling toxic fumes and particles is significantly minimized.

- Personal Protective Equipment

- Personal protective equipment plays a vital role in safeguarding individuals against the health risks associated with soldering. Respiratory masks and safety goggles provide essential protection, particularly in environments with limited ventilation. Proper usage of personal protective equipment is paramount for minimizing exposure to hazardous fumes.

- Adherence to Proper Soldering Practices

- Adhering to proper soldering practices is imperative for creating a safe soldering work environment. This includes avoiding overheating, using lead-free solder whenever possible, and following recommended safety guidelines. By implementing best practices, the overall health risks associated with soldering fumes can be significantly mitigated.

Suggestions for Alternative Products on Amazon

Exploring alternative products can further reduce the health risks associated with soldering fumes. Consider the following options:

- Lead-Free Solder Lead-free solder is a safer alternative to traditional solder that contains lead. It is composed of metals like tin, silver, and copper, which are less harmful to human health. Using lead-free solder can significantly reduce the risk of lead poisoning.

- Rosin-Free Flux Rosin-free flux is another alternative that helps minimize health risks. Traditional flux contains rosin, which can cause respiratory issues and occupational asthma. Opting for rosin-free flux, such as acid paste flux, reduces these risks while still providing effective soldering performance.

- Water-Soluble Flux Water-soluble flux is a safer option than traditional flux. It can be easily cleaned with water, reducing the need for harsh chemicals and solvents that can pose additional health risks.

- Fume Extractors Investing in high-quality fume extractors can effectively remove harmful fumes from the soldering area, ensuring cleaner air and a safer working environment. Look for models with HEPA filters for optimal performance.

By integrating these alternative products into your soldering practices, you can further mitigate the health risks associated with soldering fumes and create a safer work environment.

Regulations and Safety Guidelines

1. Occupational Safety and Health Administration (OSHA) Standards

Soldering is a common activity in many industries, and the Occupational Safety and Health Administration (OSHA) has established comprehensive standards and regulations to address the potential health risks associated with soldering and occupational exposure to hazardous substances. These standards not only ensure workplace safety but also promote compliance with legal regulations.

Here are some key aspects of OSHA standards related to soldering:

- Ventilation Requirements: OSHA standards outline specific requirements for ventilation systems to effectively remove soldering fumes from the work environment. Proper ventilation is crucial in preventing the accumulation of hazardous airborne contaminants.

- Permissible Exposure Limits: OSHA sets permissible exposure limits (PELs) for various hazardous substances, including those generated during the soldering process. Adhering to these limits is essential for protecting workers from overexposure to harmful fumes and particulates.

- Personal Protective Equipment (PPE): OSHA standards mandate the use of appropriate personal protective equipment, such as respiratory protection, gloves, and eye protection, to safeguard workers from the adverse effects of soldering fumes and other occupational hazards.

Compliance with OSHA standards is critical for maintaining a safe working environment and minimizing the health risks associated with soldering activities. By following these regulations, companies can protect the well-being of their employees and demonstrate a commitment to workplace safety.

2. European Union Restrictions

The European Union has implemented strict regulations and directives aimed at safeguarding the health and safety of workers involved in soldering activities. These regulations are designed to mitigate the risks associated with hazardous substances commonly found in soldering fumes. Compliance with these regulations is essential for ensuring a secure working environment and the well-being of individuals engaged in soldering processes.

Conclusion

Understanding the health risks of soldering fumes is paramount for creating safe working environments and promoting occupational well-being. By comprehensively examining the composition of soldering fumes, exposure risks, health effects, safety measures, regulations, and safety guidelines, individuals and organizations can make informed decisions to mitigate the potentially harmful impact of soldering fumes. Prioritizing safety measures, adherence to regulatory standards, and proactive risk management are essential for safeguarding the health of individuals engaged in soldering activities.