Can I use hot air gun for soldering?

Introduction

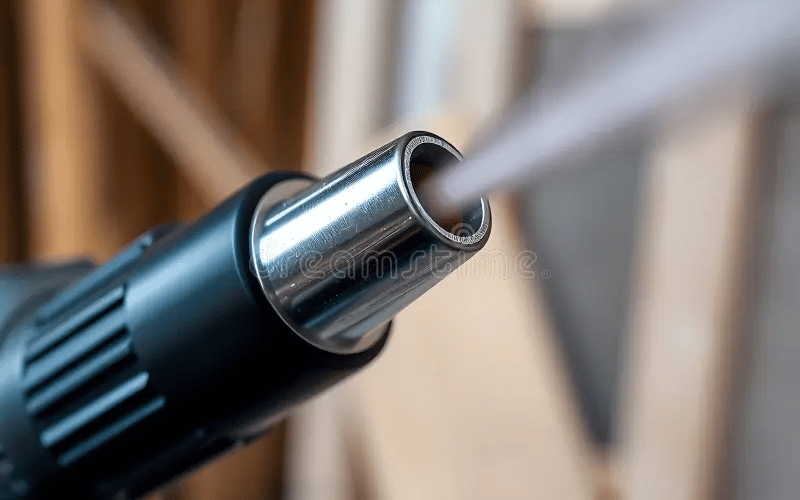

Can I use a hot air gun for soldering? This question often arises when considering the right tools for soldering applications. In this comprehensive guide, we will explore the practicality of using a hot air gun for various soldering applications. We will delve into its benefits, limitations compared to traditional soldering tools, and the types of projects it’s best suited for. Additionally, we will cover the techniques involved, essential safety tips, and provide valuable insights to help you decide if a hot air gun is the right tool for your soldering needs.

Answer to the Question

Using a hot air gun for soldering is not only practical but also offers several advantages. Its versatility, temperature control, and precision soldering capabilities make it a valuable tool for a wide range of soldering tasks, particularly in electronics and delicate applications. Understanding the benefits and tips for using a hot air gun for soldering is essential for achieving precise and effective results.

Benefits of Using a Hot Air Gun for Soldering

Versatility

A hot air gun for soldering offers remarkable versatility in soldering applications. Its ability to evenly distribute heat across various components and materials makes it suitable for a wide range of tasks.

- Reflow Soldering: The hot air gun is ideal for reflow soldering, ensuring that the solder is melted and flowed to create strong and reliable joints.

- Heat-Shrink Tubing: When it comes to heat-shrink tubing, the hot air gun provides even heating to shrink the tubing around wires and connectors, offering a secure and professional finish.

- Desoldering: This versatile tool is also effective for desoldering, allowing for the removal of components and old solder from circuit boards with precision and ease.

Furthermore, the hot air gun’s versatility extends to its application in various industries and tasks outside of electronics, such as automotive repairs, plastic fabrication, and even craft and DIY projects.

Temperature Control

Temperature control is a crucial and fundamental aspect when utilizing a hot air gun for soldering. This feature allows the user to precisely set and regulate the temperature, ensuring that even the most delicate components are not adversely affected during the soldering process. The ability to fine-tune the temperature provides consistent and reliable results when working with various materials and heat requirements.

- Safe Soldering: The precise temperature control minimizes the risk of overheating, which is essential for protecting sensitive electronic components from damage.

- Customized Settings: Users can tailor the temperature settings to suit different types of solder and specific soldering tasks, ensuring optimal performance and quality.

- Enhanced Productivity: With accurate temperature control, the soldering process becomes more efficient, leading to increased productivity and high-quality workmanship.

Precision Soldering

When it comes to precision soldering, a hot air gun offers a wide range of capabilities that enable accurate and controlled application of heat. Here’s a detailed look at the precision soldering features and benefits provided by hot air guns:

- Focused Heat Distribution: Hot air guns are designed to provide a concentrated and focused heat distribution, allowing for precise heating of specific areas. This is particularly advantageous when working on intricate soldering tasks that require pinpoint accuracy.

- Enhanced Maneuverability: The maneuverability of a hot air gun allows for easy navigation around components and circuitry, ensuring that the heat is applied precisely where needed without the risk of damage to surrounding areas.

- Temperature Stability: Hot air guns offer consistent and stable temperature control, which is essential for achieving reliable and durable soldering connections. The ability to maintain a steady temperature throughout the soldering process is crucial for producing high-quality results.

- Reduced Risk of Overheating: With precision temperature control, hot air guns help minimize the risk of overheating delicate components, circuit boards, and electronic elements, contributing to increased reliability and longevity of the soldered connections.

Tips for Using a Hot Air Gun for Soldering

Choosing the Right Nozzle

When it comes to selecting the right nozzle for a hot air gun, several factors need to be considered to ensure optimal soldering results. The right choice of nozzle size, shape, and material can significantly impact the airflow, heat distribution, and overall soldering process.

- Nozzle Size: The size of the nozzle directly affects the airflow and heat concentration. A smaller nozzle provides more focused heat, ideal for precision work, while a larger nozzle offers greater coverage for larger soldering tasks.

- Nozzle Shape: Different nozzle shapes, such as chisel, conical, and angled, are suitable for specific soldering tasks. The shape can influence the heat distribution and the accessibility to tight spaces.

- Nozzle Material: Nozzles are available in various materials such as stainless steel, ceramic, and brass. Each material has unique heat conduction properties, durability, and compatibility with different soldering applications.

Matching the specific soldering task with the appropriate nozzle is crucial for achieving the desired soldering outcome. Whether it’s precision soldering on small electronic components or larger soldering projects, having the right nozzle ensures efficiency, accuracy, and quality in the soldering process. By understanding the various factors that influence the choice of nozzle, soldering operators can make informed decisions to optimize their soldering operations.

Maintaining the Right Distance

Maintaining the correct distance between the hot air gun and the soldering components is vital to prevent damage and achieve effective results. Keeping an optimal distance ensures that heat is evenly distributed without causing overheating or damage to the delicate components. Maintaining the right distance is a key factor in achieving successful and reliable soldering outcomes.

- Component Sensitivity: Different components have varying levels of sensitivity to heat. Understanding the sensitivity of the components being soldered is crucial for determining the appropriate distance between the hot air gun and the components.

- Nozzle Size: The size of the nozzle on the hot air gun can impact the distance needed for effective soldering. Larger nozzles may require a greater distance to disperse heat evenly, while smaller nozzles may need a closer proximity to the components.

- Airflow Strength: The strength of the airflow from the hot air gun influences the distance needed for optimal soldering. High airflow may necessitate a greater distance to prevent overheating, whereas lower airflow might require a closer distance for adequate heat distribution.

When soldering components, it’s important to employ techniques that ensure the maintenance of the right distance between the hot air gun and the components:

- Continuous Monitoring: Regularly monitor the distance between the hot air gun and the components throughout the soldering process to maintain a consistent and safe distance.

- Practice Precision: Develop the skill of maintaining a steady and precise distance, especially when working with delicate or intricate components.

- Utilize Tools: Consider utilizing tools such as standoff clips or height-adjustable stands to help regulate and maintain the appropriate distance during soldering operations.

Preheating the Component

Preheating the soldering component before solder application is a beneficial technique when using a hot air gun. This process helps in preparing the surface and ensuring that the solder adheres effectively to the component. By preheating the component, the soldering process becomes more efficient, allowing for better adhesion and reliable connections.

- Increased Thermal Performance: Preheating the component enhances its thermal performance, making it more receptive to the solder and preventing thermal shock.

- Improved Solder Flow: The application of heat to the component facilitates better flow and distribution of the solder, resulting in more consistent and robust connections.

- Preventing Component Damage: Preheating helps to prevent thermal stress and potential damage to sensitive components during the soldering process.

Safety Precautions When Using a Hot Air Gun for Soldering

Work in a Well-Ventilated Area

When using a hot air gun for soldering, it is crucial to work in a well-ventilated area to minimize the risk of inhalation of fumes and ensure optimal airflow. Here are some additional details to consider:

- Positioning: Place yourself in such a way that the fumes are directed away from your breathing zone. This helps in reducing the chances of inhaling potentially harmful substances.

- Ventilation Systems: If available, use local exhaust ventilation systems to capture and remove fumes directly at the source. This is especially beneficial when working indoors or in confined spaces.

- Outdoor Soldering: When possible, consider outdoor soldering to benefit from natural ventilation and reduce the concentration of fumes in the immediate working environment.

- Monitoring Air Quality: Employ air quality monitors to ensure that the level of harmful substances in the air remains within safe limits and to prompt action if necessary.

By following these guidelines and maintaining a focus on the importance of working in a well-ventilated area, you can significantly enhance the safety of the soldering process.

Use Heat-Resistant Materials

When it comes to using a hot air gun for soldering, employing heat-resistant materials is crucial for safety and efficiency. Heat-resistant materials are designed to withstand high temperatures, making them essential for preventing damage and ensuring a smooth soldering process.

Types of Heat-Resistant Materials:

- Silicone pads: These are ideal for protecting work surfaces from heat and preventing damage to the surrounding area. They can withstand temperatures up to 600°F, making them suitable for soldering applications.

- Ceramic tiles: Known for their ability to endure high temperatures, ceramic tiles provide a durable and heat-resistant surface for soldering work. They are an excellent choice for creating a safe and stable work area.

- Heat-Resistant Gloves: Using gloves made from heat-resistant materials can help protect your hands from high temperatures and potential burns during the soldering process. Look for gloves designed specifically for soldering work to ensure maximum safety.

By utilizing these heat-resistant materials, soldering tasks can be carried out with confidence, knowing that the work surface and surroundings are protected against the intense heat of the hot air gun.

Protective Gear

When working with hot air guns for soldering, it is crucial to prioritize safety by using appropriate protective gear. Protective gear serves as a barrier against potential hazards and ensures the well-being of the individual conducting the soldering task. Here are some essential protective gear items to consider:

- Heat-Resistant Gloves: Utilize gloves specifically designed to withstand high temperatures, providing protection against burns and thermal exposure.

- Goggles: Invest in high-quality goggles to shield the eyes from potential injuries caused by sparks, heat, or fumes.

- Apron: Wear a durable apron to protect clothing from soldering flux, hot air, and splattering molten metal.

- Respirator: Use a respirator or mask to prevent inhalation of harmful soldering fumes, ensuring respiratory safety.

Additionally, it’s important to choose protective gear that fits properly and is comfortable to wear for extended periods, promoting ease of movement and reducing fatigue. By incorporating these protective measures, individuals can confidently engage in soldering tasks while prioritizing their safety and well-being.

Conclusion

Understanding the practicality of using a hot air gun for soldering is essential for individuals engaged in various soldering tasks. The benefits of versatility, temperature control, and precision soldering make it a valuable tool for electronics, circuit boards, and delicate soldering applications. The tips for choosing the right nozzle, maintaining the proper distance, and preheating components enhance the efficiency and effectiveness of the soldering process. Additionally, following safety precautions creates a secure working environment and minimizes potential risks. By exploring the uses, benefits, and safety measures associated with a hot air gun for soldering, individuals can make informed decisions about its suitability for their specific soldering needs.