Can I solder copper pipe with a heat gun?

Introduction

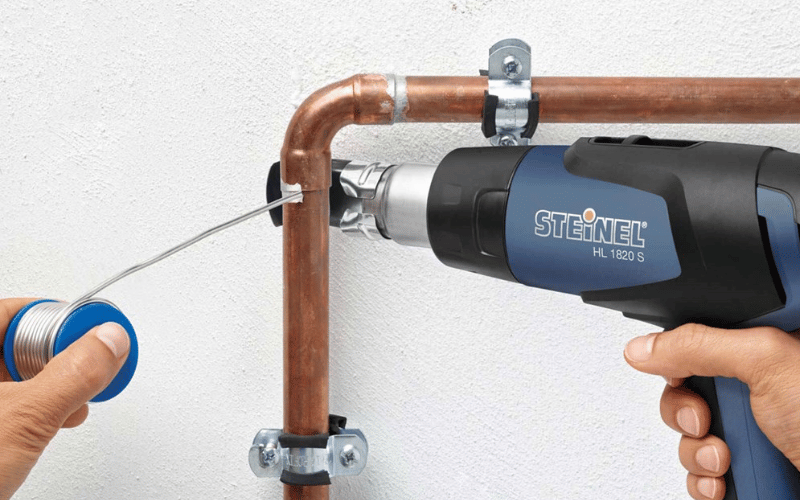

Soldering copper pipes can be a challenging task, especially if you’re exploring alternative methods to traditional torch soldering. One such alternative that has gained attention is soldering with a heat gun. In this comprehensive guide, we’ll delve into the process of soldering copper pipes with a heat gun, its benefits, tips for successful soldering, safety measures, and much more. Whether you’re a seasoned DIY enthusiast or a plumbing professional, this article aims to provide valuable insights into the effectiveness, limitations, and best practices of soldering with a heat gun.

Answer to the Question

Before we delve into the specifics of soldering copper pipes with a heat gun, let’s address the burning question: Can I solder copper pipe with a heat gun? The answer is a resounding yes. Soldering copper pipes with a heat gun is indeed a viable alternative to the conventional torch method. However, it’s essential to understand the process, limitations, and necessary tools to ensure effective soldering. In the subsequent sections, we’ll explore the benefits, tips for successful soldering, safety measures, and conclude with a comprehensive overview of this alternative soldering method.

Benefits of Soldering with a Heat Gun

Efficiency and Speed

One of the notable benefits of using a heat gun for soldering is the efficiency and speed it offers. Let’s delve into more details to fully understand the advantages:

- Localized Heating: Unlike traditional torch soldering that requires heating the entire fitting, a heat gun allows for targeted and localized heating. This not only saves time but also minimizes energy consumption.

- Faster Soldering: The controlled application of heat leads to faster melting of the solder, which significantly reduces the overall soldering time. This efficiency is particularly beneficial in high-production environments where time is of the essence.

- Precision and Consistency: The ability to apply heat only to specific areas results in precise and consistent soldering. This is especially advantageous when working with delicate components or intricate designs.

It’s evident that the efficiency and speed offered by a heat gun in soldering operations provide numerous advantages, from saving time and energy to ensuring accuracy and consistency.

Versatility and Accessibility

Soldering with a heat gun offers a multitude of benefits due to its versatility and accessibility. Let’s explore how these factors contribute to its usefulness:

- Adaptability: The heat gun is remarkably adaptable, capable of handling a wide range of projects. Whether it’s repairing copper pipes, working on electronic circuits, or crafting jewelry, the heat gun proves to be a reliable tool across various domains.

- Customization: Its ability to solder various copper pipe fittings in different scenarios allows for customization based on the specific requirements of each project. This level of flexibility ensures that the final result meets the desired specifications with precision.

- Accessibility: With heat guns readily available in most home improvement stores, they are easily accessible to DIY enthusiasts and professionals alike. This makes it a convenient tool to add to one’s arsenal for any soldering needs.

- Wide Applications: The heat gun is not limited to a specific industry or trade. Its versatility allows it to be utilized in plumbing, automotive repair, electronics, arts and crafts, and various other fields, making it an indispensable tool in diverse settings.

Tips for Successful Soldering with a Heat Gun

Proper Heat Control

When soldering with a heat gun, proper heat control is crucial to achieving successful results. It’s essential to use the appropriate heat setting on the gun to ensure that the copper pipe and fittings reach the required temperature for soldering. Experimenting with the heat settings on scrap pieces of copper pipe can help in understanding the ideal temperature for effective soldering.

- Understanding the Heat Settings

- Heat Distribution

- Temperature Monitoring

Proper heat control involves several key considerations that ensure the soldering process is carried out effectively and safely:

- Understanding the Heat Settings: Different heat guns have varying temperature settings, and it’s important to comprehend the range of heat levels to choose the most suitable one for the task at hand.

- Heat Distribution: Proper heat control also involves ensuring that the heat is distributed evenly across the surface of the copper pipe and fittings, allowing for uniform soldering.

- Temperature Monitoring: Monitoring the temperature of the copper pipe using a thermometer or temperature-sensitive materials is crucial for achieving the desired soldering temperature without causing damage.

By paying close attention to these factors, practitioners can execute proper heat control, resulting in reliable and durable soldered joints.

Appropriate Soldering Technique

When it comes to achieving a successful soldering outcome with a heat gun, mastering the appropriate soldering technique is essential. Let’s delve into the key aspects of this technique and how they contribute to a reliable and durable joint.

- Proper Flux Application: Before commencing the soldering process, it’s crucial to apply flux to the joint. The flux not only cleans the surfaces but also enables the solder to adhere effectively.

- Even Heat Distribution: Ensuring uniform heating across the joint area is vital to promote the smooth flow and adhesion of the solder. This prevents cold spots and ensures a strong bond.

- Smooth Solder Application: Applying the solder at the joint of the heated copper fittings and allowing it to flow around the connection is crucial for a secure and leak-free joint. Care should be taken to avoid excess solder, which can lead to problems such as drips and an uneven joint.

- Observation of Joint Fill: It’s important to watch for the complete fill of the joint with solder. A properly filled joint indicates a successful soldering process.

- Effective Cleaning: Once the soldering is complete, it’s essential to clean the joint thoroughly to remove any residual flux and ensure a tidy finish.

Safety Measures for Soldering with a Heat Gun

Protective Gear and Ventilation

When engaging in soldering with a heat gun, it is crucial to prioritize personal safety and respiratory health. This can be achieved through the proper use of protective gear and ventilation. Here’s a detailed look at the essential elements:

- Heat-Resistant Gloves: These gloves provide optimal protection against burns and heat-related injuries during the soldering process. It is important to choose gloves that offer dexterity and a secure grip while also ensuring heat resistance.

- Safety Goggles: Soldering involves exposure to intense heat and potentially hazardous particles. Thus, safety goggles are indispensable for shielding the eyes from sparks, splashes, and fumes, thereby preventing eye injuries and irritation.

- Well-Ventilated Area: Working in a well-ventilated space is fundamental for dissipating fumes generated by the flux and solder. This helps to mitigate the inhalation of harmful substances, promoting respiratory well-being.

In addition, an effective ventilation system aids in maintaining a safe environment by minimizing the accumulation of toxic fumes. It is advisable to position the ventilation source strategically to capture and expel the fumes efficiently. Proper ventilation reduces the risk of inhaling harmful fumes and contributes to a conducive working space.

Precautions for Surrounding Materials

- Use heat-resistant shielding to protect adjacent surfaces

- Utilize non-flammable materials to safeguard surroundings from heat exposure

- Maintain a fire-safe workspace by being mindful of the proximity of flammable materials

- Implement fire-resistant barriers to prevent accidental fires during soldering

- Store flammable materials in designated locations away from the soldering area

Conclusion

In conclusion, the option to solder copper pipes with a heat gun provides a viable alternative to traditional torch soldering, presenting benefits such as efficiency, speed, versatility, and accessibility. By adhering to the proper heat control, soldering technique, and safety measures, DIY enthusiasts and professionals can effectively utilize heat guns for various soldering projects. Whether it’s plumbing repairs or smaller DIY tasks, the ability to solder copper pipes with a heat gun offers a practical solution with notable advantages.