What is a good soldering iron for beginners?

Introduction

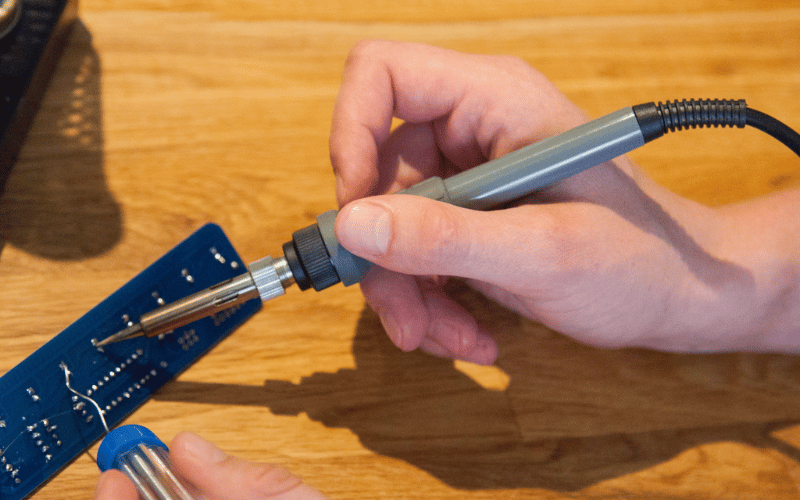

Welcome to the world of soldering! Whether you’re delving into electronics, crafts, or small repairs, the right soldering iron is a crucial tool for beginners. This comprehensive guide will equip you with invaluable knowledge to select the perfect soldering iron, learn essential safety tips, and avoid common mistakes. Let’s delve into the key aspects that will shape your soldering journey and help you build confidence in your skills.

Answer to the Question

When looking for a good soldering iron for beginners, it’s essential to consider key features that ensure a seamless and safe soldering experience. Additionally, understanding the types of soldering irons suitable for newcomers and the associated safety tips and common mistakes to avoid is critical. This comprehensive article will provide you with expert advice and detailed insights to help choose the ideal soldering iron for your needs, guiding you through the exciting journey of mastering this fundamental skill.

Key Features to Look for in a Soldering Iron

Temperature Control

Temperature control is a critical aspect of soldering, as it directly impacts the quality of the solder joints. Here are some key points to consider:

- Precise Adjustment: Look for a soldering iron that offers precise temperature adjustment, allowing you to set the exact temperature required for the specific soldering task.

- Temperature Stability: A good soldering iron maintains a stable temperature during operation, ensuring consistent performance and reliable soldering results.

- Variable Settings: Consider a soldering iron with variable temperature settings, as different soldering tasks may require varying degrees of heat.

- Rapid Response: The ability of the soldering iron to rapidly reach and maintain the set temperature is essential for efficient soldering processes.

- Digital Display: Soldering irons with digital temperature displays provide clear visibility of the current temperature, aiding precise adjustments and monitoring.

It is important to select a soldering iron with temperature control features that align with your specific soldering requirements, ensuring optimal results and workmanship quality.

Wattage and Heat-Up Time

When choosing a soldering iron, it’s important to consider the wattage and heat-up time as these factors greatly impact the soldering process. Let’s dive deeper into these aspects:

- Wattage: The wattage of a soldering iron determines how quickly it can transfer heat to the joints being soldered. A higher wattage iron can heat up faster and maintain temperature more effectively, making it suitable for heavy-duty soldering tasks. On the other hand, lower wattage irons are better suited for delicate electronic components to prevent heat damage.

- Heat-Up Time: The heat-up time refers to the duration it takes for the soldering iron to reach the desired operating temperature. Faster heat-up times can improve efficiency and reduce waiting, especially during extended soldering sessions.

It’s important to find the right balance between wattage and heat-up time, based on the type of soldering work you’ll be doing. For intricate and detailed work, a lower wattage iron with a quick heat-up time might be more suitable, while heavy-duty soldering projects may require a higher wattage iron with a slightly longer heat-up time.

Tip Variety and Durability

In soldering, the tip of the soldering iron plays a crucial role in the quality of the solder joints and the overall user experience. Here, we will delve into the intricate details of tip variety and durability, equipping you with the knowledge necessary to make informed decisions when choosing a soldering iron.

- Chisel Tips: These tips are designed for general soldering applications and provide a broad surface for efficient heat transfer. They are suitable for through-hole and surface mount soldering.

- Conical Tips: Ideal for precision work, conical tips are tapered to a point, allowing for pinpoint accuracy when soldering small components or working with densely populated circuit boards.

- Bevel Tips: Offering a combination of the advantages of chisel and conical tips, bevel tips are versatile and well-suited for various soldering tasks.

When evaluating the durability of soldering iron tips, consider the following factors:

- Material Composition: High-quality tips are typically made of copper, iron, nickel, and chromium alloys, providing robustness and resistance to wear.

- Coating: Look for tips with durable coatings such as iron plating, nickel plating, or chromium plating, which enhance longevity and prevent oxidation.

- Heat Resistance: Ensure that the tips can withstand high temperatures without degrading, allowing for prolonged use without compromising performance.

Types of Soldering Irons for Beginners

Pencil Soldering Irons

Pencil soldering irons are one of the most common types of soldering irons used by beginners and professionals alike. They are lightweight, easy to handle, and versatile, making them ideal for a wide range of soldering tasks.

- Features of Pencil Soldering Irons:

- Compact and portable

- Quick heating time

- Adjustable temperature settings

- Interchangeable tips for different soldering tasks

- Common Uses: Pencil soldering irons are commonly used for soldering electronic components, circuit boards, small wires, and other delicate soldering projects. They are also suitable for precision soldering in hobbyist and DIY projects.

- Tips for Working with Pencil Soldering Irons: It is important to keep the soldering tip clean to ensure good heat transfer and solder flow. Additionally, using the right tip for the specific soldering task is crucial for achieving optimal results.

Soldering Stations

Soldering stations are essential tools for electronics enthusiasts and professionals. They provide a controlled environment for soldering electronic components with precision and reliability. In this section, we will delve into the key features, advantages, and types of soldering stations.

When choosing a soldering station, it’s important to consider the following key features:

- Temperature Control: Soldering stations offer precise temperature control, allowing users to adjust the heat according to the requirements of the soldering task.

- Station Durability: High-quality soldering stations are built to last, providing durability and reliability for long-term use.

- Integrated Stands: Many soldering stations come with integrated stands for securely holding the soldering iron when not in use.

- ESD Safe: Some soldering stations are designed to be electrostatic discharge (ESD) safe, which is crucial for working with sensitive electronic components.

There are several advantages to using soldering stations over traditional soldering irons:

- Precision: Soldering stations provide precise temperature control, resulting in accurate and consistent solder joints.

- Enhanced Safety: With built-in safety features, soldering stations reduce the risk of accidental burns and electrical hazards.

- Efficiency: The adjustable temperature settings and ergonomic designs of soldering stations contribute to efficient soldering processes.

- Versatility: Soldering stations are suitable for a wide range of soldering tasks, from intricate circuit board work to larger soldering projects.

Soldering stations come in various types, each catering to specific soldering needs. Some common types include:

TypeDescriptionPrecision Soldering StationsDesigned for detailed and delicate soldering tasks that require high precision.Digital Soldering StationsEquipped with digital displays and advanced temperature control for professional soldering applications.Portable Soldering StationsCompact and travel-friendly soldering stations suitable for on-the-go projects.

Safety Tips for Beginner Soldering Projects

Workspace Preparation

Before starting any soldering project, it’s important to properly prepare your workspace. A well-prepared workspace contributes to both safety and efficiency during soldering. Here are some key considerations for workspace preparation:

- Clear the workspace: Ensure that the area is clear of clutter and unnecessary items. This will provide ample space for your soldering equipment and minimize the risk of accidents.

- Well-ventilated area: Soldering can produce fumes that may be harmful if inhaled. It’s crucial to work in a well-ventilated area to disperse these fumes. If possible, use a fume extractor or work near an open window.

- Lighting: Adequate lighting is essential for precision soldering. Make sure your workspace is well-lit to clearly see the components and solder joints.

- Heat-resistant surface: Use a heat-resistant mat or surface to protect your workspace from heat damage. This is particularly important when working with a soldering iron or hot air rework station.

- Organize tools and materials: Keep your tools, components, and materials well-organized and within easy reach. This will streamline the soldering process and reduce the likelihood of errors.

Proper Handling and Ventilation

- When handling soldering equipment, it’s important to prioritize safety and proper techniques.

- Always use a soldering iron stand when not in use to prevent accidental burns or fires.

- Ensure adequate ventilation in the workspace to minimize exposure to solder fumes. This can be achieved by working near a window or using a fume extractor.

Safety Equipment

When it comes to soldering, safety should always be a top priority. The proper safety equipment ensures that you can work confidently and without unnecessary risks. Here are the essential safety tools and equipment you should have for any soldering project:

- Safety goggles: Protect your eyes from potential splashes of molten solder and harmful fumes.

- Heat-resistant gloves: Essential for handling hot soldering irons and protecting your hands from burns.

- Fire extinguisher: Have a fire extinguisher nearby in case of any unexpected fires from soldering mishaps.

- Fume extractor: Helps to remove harmful fumes and particles from the air, keeping your workspace safe and clean.

- Respirator mask: A respirator or mask with appropriate filters can safeguard your lungs from inhaling soldering fumes.

- Exhaust fan: Using an exhaust fan in your workspace improves ventilation and reduces the concentration of potentially hazardous fumes.

- Soldering iron stand: Prevents accidental burns and fires by providing a secure place to rest the hot soldering iron.

Remember, these are just the basic safety equipment items. Always assess the specific risks of your soldering project and ensure you have the necessary protective gear.

Common Mistakes to Avoid for Beginner Soldering

Overheating Components

Overheating components in soldering can lead to irreversible damage and poor electrical connections. It is crucial for soldering enthusiasts, especially beginners, to understand the risks associated with overheating components and how to prevent them. Here are some important points to consider when dealing with overheating components:

- Understanding thermal limits: Every electronic component has a specified temperature limit that should not be exceeded during soldering. It is essential to refer to the component’s datasheet or technical specifications to determine its maximum temperature threshold.

- Use of appropriate soldering tools: Investing in a quality soldering iron with adjustable temperature settings can greatly reduce the risk of overheating components. Temperature-controlled soldering stations allow precise regulation of heat, ensuring that components are not exposed to excessive temperatures.

- Proper technique and timing: Practicing proper soldering technique, such as using the right amount of solder and avoiding prolonged exposure to heat, can significantly minimize the likelihood of overheating components. Additionally, it is important to maintain a brief contact time between the soldering iron and the component to prevent overheating.

- Visual inspection: After soldering, inspect the components for any signs of overheating, such as discoloration, distortion, or damage to the surrounding PCB. Visual inspection helps in identifying potential issues caused by excessive heat.

Using Excessive Solder

When it comes to soldering, using excessive solder can lead to a range of problems and negative outcomes. It’s important to understand the impacts of using too much solder and how to avoid this common mistake.

Here are some of the consequences of using excessive solder:

- Excess solder can create short circuits between adjacent pads and pins.

- It can lead to solder bridges, which disrupt the electrical connections between components.

- Overheating can occur due to the prolonged application of excessive solder, potentially damaging sensitive electronic components.

To prevent the use of excessive solder, consider the following tips:

- Practice controlling the amount of solder applied during the soldering process.

- Use the right soldering iron and tip size to ensure precise solder application.

- Inspect the solder joints to ensure they are well-formed without any excess solder.

Improper Cleaning

Improper cleaning is a common mistake that beginners make when soldering. It is important to clean the soldered area properly to ensure the longevity and functionality of the soldered components. Improper cleaning can lead to various issues such as poor electrical connections, corrosion, and degradation of the soldered joint over time. Here are some key points to consider when it comes to proper cleaning:

- Use of appropriate cleaning agents: Choosing the right cleaning agents is crucial to effectively remove flux residues and other contaminants. Isopropyl alcohol and dedicated flux removers are commonly used for cleaning soldered joints.

- Techniques for cleaning: Employing gentle brushing or wiping techniques can help in removing residual flux and contaminants without causing damage to the soldered components.

- Inspection after cleaning: After cleaning the soldered area, it is important to inspect the joints thoroughly to ensure that all residues have been effectively removed. Use of magnification tools can aid in detailed inspection.

- Preventing re-contamination: Once the cleaning process is complete, it is essential to handle the soldered components with care to prevent re-contamination. Proper storage and handling practices should be followed to maintain the cleanliness of the soldered joints.

Conclusion

In conclusion, finding the right soldering iron for beginners can be a daunting task. However, armed with the knowledge of key features to look for, types of soldering irons available, and safety tips to keep in mind, you can confidently choose the perfect tool for your needs. Remember to prioritize adjustable temperature, ergonomic design, and safety features when making your selection.

For those just starting out in the world of soldering, a pencil soldering iron or soldering station are great options to consider. These types of irons offer ease of use and versatility for a variety of projects. And don’t forget to properly prepare your workspace, handle the iron with care, and use safety equipment to ensure a successful and safe soldering experience.

As you embark on your soldering journey, keep in mind the common mistakes to avoid, such as overheating components, using excessive solder, and improper cleaning. By following these tips and techniques, you can confidently and safely hone your soldering skills and take on more advanced projects. So go ahead and choose the perfect soldering iron for beginners and start creating with confidence!