DIY Soldering Iron Holder: A Step-by-Step Guide

Introduction

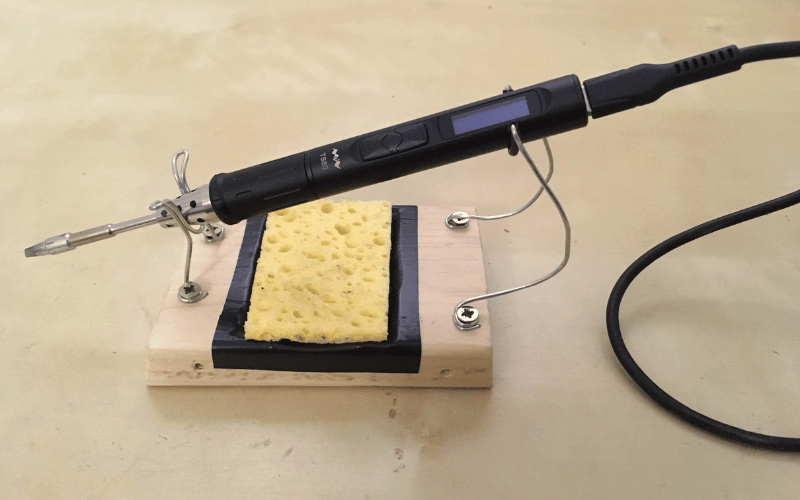

Welcome to the world of soldering! Whether you’re a seasoned DIY enthusiast or just getting started, having a reliable soldering iron holder is essential for a safe and organized workspace. In this comprehensive guide, we’ll explore the key features of a soldering iron holder, the importance of using one, and how to create your very own DIY soldering iron holder. We’ll cover everything from necessary tools and materials to step-by-step instructions, ensuring that you can enhance your soldering setup with creativity and practicality.

What is a Soldering Iron Holder?

Key Features of a Soldering Iron Holder

- Adjustable clamps to hold the soldering iron firmly in place

- Heat-resistant material to protect the work surface from damage

- Storage compartments for solder wire, tips, and other accessories

Types of Soldering Iron Holders

Soldering iron holders come in a variety of types, each designed to meet different needs and preferences. Below are the most common types of soldering iron holders:

- Stand Holders: These are the most traditional type of soldering iron holders, featuring a stable base and a metal loop to hold the iron.

- Magnetic Holders: Ideal for quick and easy access, magnetic holders use powerful magnets to securely hold the soldering iron in place.

- Spring Coiled Holders: These holders utilize a spring mechanism to hold the soldering iron firmly in place, allowing for easy insertion and removal.

- Vacuum De-soldering Gun Holders: Specifically designed for de-soldering, these holders provide a secure place to store de-soldering guns when not in use.

- Portable Holders: Designed for convenience, portable holders are lightweight and easy to transport, making them suitable for on-the-go projects.

Importance of Using a Soldering Iron Holder

Safety Benefits

- Protection against burns and injuries

- Prevention of accidental fires

Using a soldering iron holder offers several safety benefits which are essential for both professionals and hobbyists. Some of these benefits include:

- Protection against burns and injuries: A soldering iron holder keeps the hot iron in a stable position, reducing the risk of accidental contact and burns. It provides a safe place to keep the iron when not in use, preventing injuries due to mishandling.

- Prevention of accidental fires: By securely holding the iron in place, the holder minimizes the risk of the iron coming into contact with flammable materials, reducing the potential for accidental fires in the workspace.

- Stability and control: The holder ensures that the iron remains stable during soldering tasks, allowing for greater control and precision, thereby minimizing the risk of accidents.

- Workplace safety compliance: Using a soldering iron holder is often a requirement in professional workshops and manufacturing environments to maintain compliance with safety regulations and standards.

Organization and Convenience

When it comes to soldering, maintaining organization and convenience is essential for efficiency and safety. Let’s delve into some key elements that contribute to a well-organized and convenient soldering setup:

- Workstation Layout: A thoughtfully organized workstation can significantly enhance the soldering experience. It’s important to arrange the soldering iron, solder, flux, and other tools within easy reach, minimizing the need for constant movement.

- Tool Storage: Utilizing dedicated storage solutions, such as soldering iron holders, solder spool stands, and component organizers, can streamline the workflow and prevent clutter on the workbench.

- Labeling and Identification: Clearly labeling containers, tools, and components not only promotes efficiency but also minimizes the risk of errors during soldering tasks. Organized labeling ensures that the right components are always within reach.

By integrating these organization techniques, soldering tasks can be carried out seamlessly, with reduced risk and increased productivity.

DIY Soldering Iron Holder: Tools and Materials

Necessary Tools for DIY Soldering Iron Holder

When embarking on a DIY project to create a soldering iron holder, it’s essential to have the right tools at your disposal. Here are the necessary tools that will help you complete this project with efficiency and precision:

- Soldering Iron: The core tool for this project. Ensure it is in good working condition with a stable and heat-resistant handle.

- Safety Goggles: Protect your eyes from potential splatter and ensure a safe working environment.

- Screwdriver Set: Necessary for assembling and securing various components of the holder.

- Drill and Drill Bits: Required for creating holes in the base or mounting surface.

- Wire Cutters/Strippers: Used for handling wires and ensuring clean and precise wire connections.

- Clamps or Vise: Aids in securing the project pieces in place during assembly.

- Measuring Tape and Ruler: Essential for precise measurements and ensuring accurate alignment of components.

- Sandpaper: Useful for smoothing out any rough edges on the holder and providing a clean finish.

- Safety Gloves: Protect your hands from sharp edges and hot surfaces during the construction process.

- Multimeter: Helps in testing connections and ensuring electrical safety.

- Wire Brushes: Useful for cleaning metal components and improving soldering connections.

By having these necessary tools on hand, you can proceed with confidence, knowing that you have everything required to create a functional and safe DIY soldering iron holder.

Materials for Creating a DIY Soldering Iron Holder

- Heat-resistant silicone mat

- Steel wire

- Wood board

Step 1: Planning Your DIY Soldering Iron Holder

Design Considerations

When planning your DIY soldering iron holder, there are several design considerations to keep in mind in order to ensure its functionality and practicality. Here are some key design considerations to consider:

- Material: Selecting the right material is crucial for the durability and heat resistance of the soldering iron holder. Common materials include heat-resistant plastics, wood, and metal alloys.

- Size and Shape: The size and shape of the holder should be determined based on the dimensions of the soldering iron and the space available in your workshop. It should adequately support the iron and be easy to access during soldering tasks.

- Heat Resistance: Ensuring that the holder can withstand the heat generated by the soldering iron is essential for safety and longevity. Consider using insulating materials or incorporating heat-resistant coatings.

- Stability: The holder should provide a stable base to prevent accidental tipping or falling. Incorporating a wide and weighted base can enhance stability.

- Accessibility: Easy accessibility to the soldering iron is important for efficiency and safety during soldering tasks. The holder should keep the iron within reach without obstructing the workspace.

Choosing the Right Location

Choosing the right location for your DIY soldering iron holder is crucial for both safety and convenience. Here are some key considerations to keep in mind:

- Workspace Accessibility: Ensure that the location is easily accessible from your primary workspace. This will minimize the time and effort required to retrieve and return the soldering iron.

- Fire Safety: Select a location that is away from flammable materials and surfaces. Additionally, consider placing a fire-resistant mat or surface under the holder as an extra safety measure.

- Ventilation: If possible, place the holder in a well-ventilated area to disperse any fumes produced during soldering.

By carefully considering these factors, you can ensure that your DIY soldering iron holder is situated in an optimal location, promoting efficient and safe soldering practices.

Step 2: Building the DIY Soldering Iron Holder

Assembly Instructions

When it comes to assembling the DIY soldering iron holder, following the instructions carefully is crucial for a successful outcome. Here are detailed assembly instructions:

- Start by laying out all the required materials and tools in a clean, well-lit workspace.

- Refer to the provided schematics and ensure that all the parts are accounted for.

- Begin by assembling the base of the soldering iron holder, following the step-by-step guide provided in the manual.

- Once the base is complete, proceed to attach the supporting arm, ensuring a stable and secure fit.

- Double-check all connections and fastenings to guarantee the structural integrity of the holder.

- Finally, test the holder with the soldering iron to ensure that it provides a stable and safe resting place.

Customization Options

When it comes to customization, the DIY soldering iron holder offers a range of options to suit your preferences and specific needs. Here are some ways you can customize your soldering iron holder:

- Color: Choose a color that matches your workspace or reflects your personal style.

- Material: Consider using different materials such as wood, metal, or plastic to customize the look and feel of the holder.

- Size: Adjust the dimensions of the holder to accommodate various types of soldering irons and accessories.

- Additional Features: Add hooks, compartments, or slots to organize soldering tools and accessories efficiently.

Step 3: Finishing Touches and Testing

Paining and Coating

Paining and coating are essential steps in the finishing process of various surfaces. It involves the application of paint, coating, or protective layers to enhance the appearance, protect against corrosion, and provide durability.

- Primer: The first layer applied to a surface to enhance adhesion and protect against corrosion.

- Basecoat: Provides the color and aesthetic appeal to the surface.

- Clearcoat: A transparent topcoat that adds gloss and protection to the basecoat.

Paints and coatings can be applied using various methods, including:

- Spray Painting: Achieves a smooth finish and efficient coverage.

- Brush Application: Offers precision and control, suitable for small areas.

- Roller Coating: Ideal for covering larger surfaces and achieving uniform thickness.

Proper surface preparation is crucial for the effectiveness of painting and coating. It includes:

- Cleaning: Removing dirt, grease, and contaminants from the surface.

- Sanding: Smoothing the surface and creating a suitable texture for adhesion.

- Priming: Applying a primer to enhance adhesion and corrosion protection.

When applying paints and coatings, environmental factors must be considered:

- Temperature and Humidity: Optimal conditions for application and curing.

- Ventilation: Proper airflow to ensure safety and quality of application.

- Environmental Regulations: Compliance with local regulations for emissions and disposal.

Ensuring Stability and Durability

When it comes to ensuring the stability and durability of any structure, there are key factors that must be taken into consideration. By addressing these factors, you can significantly enhance the longevity and robustness of the finished product.

The choice of materials plays a crucial role in the stability and durability of any construction project. For instance, the use of high-quality, weather-resistant materials such as stainless steel or treated timber can effectively mitigate the risks of corrosion and decay, thereby extending the lifespan of the structure.

Building a strong foundation is essential for ensuring stability. This involves expertly preparing the ground, using appropriate footing and reinforcement, and ensuring proper drainage. A solid foundation provides the structural support necessary to withstand natural elements and external forces.

Integrating a robust design and construction methods is instrumental in enhancing stability and durability. This includes employing proven architectural and engineering principles, as well as adhering to industry best practices in construction techniques and methodologies.

Sustaining stability and durability requires diligent maintenance practices. This involves periodic inspections, timely repairs, and the application of protective coatings to prevent deterioration. By implementing a comprehensive maintenance schedule, the structural integrity can be preserved for an extended period.

Understanding and adapting to environmental factors is vital in ensuring stability and durability. Accounting for seismic activity, wind loads, temperature variations, and other environmental challenges is essential for designing structures that can withstand these conditions without compromising integrity.

Conclusion

Congratulations, you’ve embarked on a journey to discover the world of soldering iron holders and unlock the creative potential of DIY projects. By understanding the significance of a soldering iron holder, exploring its key features, and venturing into the realm of DIY construction, you’ve gained valuable insights into enhancing your soldering setup. Whether you’re a hobbyist, enthusiast, or professional, the functionality and practicality of a customized soldering iron holder add a touch of personal craftsmanship to your workspace. Embrace the creativity, safety, and organization that a soldering iron holder brings, and continue to explore new horizons in the world of soldering!