DIY Soldering Projects for Beginners: Step-by-Step Guide

Introduction

Welcome to the world of soldering, where creativity and technical skills combine to bring electronic projects to life. Whether you’re a beginner or an enthusiast, this guide will take you through the basics of soldering, safety measures, essential supplies, techniques, DIY projects, and common mistakes to avoid. Let’s dive in and explore the fascinating world of soldering.

What is Soldering?

Understanding the Basics of Soldering

Soldering is a fundamental process in electronics that involves joining metal components by melting a filler metal, known as solder, at relatively low temperatures. This creates a permanent connection, allowing electricity to flow between the components. It’s a versatile and essential skill for DIY enthusiasts, hobbyists, and professionals working with electronic circuits and components.

Importance of Safety Measures in Soldering

Soldering is a precise and skillful technique used in electronic assembly and repair. While it enables the creation of reliable electrical connections, it involves inherent risks due to the high temperatures and potentially hazardous materials involved. Prioritizing safety measures in soldering is crucial for protecting the craftsman and ensuring the integrity of electronic projects. Let’s delve into the essential safety measures to uphold during soldering:

- Proper Ventilation: Adequate ventilation is vital in soldering workspaces to dissipate fumes and maintain air quality. This can be achieved through the use of fume extractors or working in well-ventilated areas with open windows or ventilation systems.

- Protective Gear: The use of personal protective equipment (PPE) is essential to minimize exposure to hazardous materials. This includes wearing heat-resistant gloves, safety goggles, and a protective apron to shield against splattering solder and flux.

- Awareness of Hazards: Understanding the potential risks associated with soldering is crucial. This includes awareness of lead exposure, burns from hot components, and the dangers of inhaling solder fumes. Appropriate safety training and knowledge of Material Safety Data Sheets (MSDS) are imperative in safeguarding against these hazards.

- Safe Handling of Equipment: Proper handling of soldering equipment is paramount. This entails ensuring the soldering iron is securely placed in a soldering stand when not in use, using the correct tips for the task at hand, and being mindful of the power source to prevent electrical hazards.

Implementing these safety measures not only protects the craftsman from immediate harm but also contributes to the longevity and success of electronic projects. By prioritizing safety in soldering, craftsmen can carry out their work with confidence and ensure the functionality and safety of the electronic components they work with.

Choosing the Right Soldering Iron

Understanding the Different Types of Soldering Irons

When it comes to choosing a soldering iron, understanding the different types available is crucial. From pencil irons to soldering stations, each type serves specific purposes and offers varying features. Beginner enthusiasts should explore the options and select a soldering iron that aligns with their projects and skill levels.

Selecting the Best Soldering Iron for Beginners

For beginners venturing into the realm of soldering, selecting the best soldering iron is the first step towards honing their skills. Factors such as wattage, temperature control, ergonomic design, and tip variety play vital roles in choosing an appropriate soldering iron that facilitates learning and practice.

When it comes to wattage, a soldering iron with adjustable wattage settings provides versatility for different soldering tasks. Lower wattages are suitable for delicate electronic components, while higher wattages are ideal for larger, heat-absorbing connections. Additionally, temperature control is essential for precision soldering. Soldering irons with temperature control features allow beginners to maintain a consistent and safe working temperature, preventing overheating and damage to components.

Ergonomic design is crucial for comfortable and extended use. Soldering irons with ergonomic handles and lightweight construction reduce hand fatigue and increase control, contributing to more precise soldering outcomes. The availability of a variety of soldering iron tips enhances the versatility of the tool. Different tip shapes and sizes cater to specific soldering tasks, providing beginners with the flexibility to work on a wide range of projects.

Furthermore, advanced safety features such as auto-sleep mode, heat-resistant stands, and insulated handles are important considerations for beginners to minimize the risk of accidents and injuries during soldering activities.

Choosing the best soldering iron for beginners is a crucial step in developing soldering skills. The right soldering iron enhances precision, efficiency, and safety in DIY soldering projects, fostering an enjoyable and successful learning experience.

Essential Soldering Supplies for Beginners

Soldering Wire and Flux

When it comes to DIY electronics projects, having the right soldering wire and flux is essential for creating reliable and durable connections. Let’s delve deeper into the significance of these two fundamental supplies:

- Soldering Wire: This is the medium through which electrical connections are established. It is crucial to choose high-quality soldering wire with the appropriate diameter to ensure a secure bond. The composition of the soldering wire, typically a combination of tin and lead, directly impacts the overall conductivity and strength of the joint.

- Flux: Flux serves a critical role in the soldering process by facilitating the cleaning and preparation of metal surfaces for soldering. It helps to remove oxides and other impurities, ensuring proper adhesion between the solder and the metals being joined. Furthermore, flux promotes the flow of solder, resulting in smoother and more uniform joints.

- Types of Flux: There are various types of flux available, each designed for specific applications. Rosin flux, also known as

Soldering Station and Workbench Setup

When setting up a soldering station and workbench for beginners, it’s important to consider the ergonomic layout and safety features. The soldering station should include adjustable temperature control, a reliable soldering iron holder, and space for additional tools such as solder, flux, and desoldering wick. A well-organized workbench setup involves adequate lighting, ample storage for electronic components, and a clear space for maneuvering during soldering tasks. Furthermore, incorporating a fume extractor or ventilation system can help maintain a clean and healthy workspace, especially when working with solder and flux. Taking the time to establish a well-equipped and well-lit soldering station coupled with an efficient workbench layout can greatly enhance the soldering experience for beginners, setting the stage for successful and satisfying projects.

Basic Soldering Techniques

Tinning the Soldering Iron Tip

Tinning the soldering iron tip is a crucial step in the soldering process. It involves coating the iron tip with a thin layer of solder, which has several important benefits:

- Protection from corrosion: The thin layer of solder creates a barrier that shields the iron tip from oxidation and corrosion, thus extending its lifespan.

- Enhanced heat transfer: Tinning enables better heat conduction, allowing the soldering iron to maintain consistent temperature and improve solder flow.

- Cleaner soldering joints: The tinned tip promotes a cleaner soldering process, resulting in more reliable and robust solder joints.

To tin the soldering iron tip effectively, follow these steps:

- Ensure the soldering iron is at the correct operating temperature for the type of solder being used.

- Wipe the soldering iron tip with a brass sponge or damp sponge to remove any residues or oxides. This ensures a clean surface for tinning.

- Apply a small amount of fresh solder to the tip, evenly coating the entire surface. The solder should melt and spread smoothly, forming a thin layer.

- Wipe the tip again to remove excess solder, leaving a thin, uniform layer that covers the entire tip.

Regular maintenance of the tinning layer is essential for optimal soldering performance. It is recommended to re-tin the soldering iron tip whenever it begins to show signs of oxidation or when solder no longer adheres easily to the tip.

Soldering Joints and Connections

Soldering joints and connections is a fundamental aspect of electronic assembly and circuit fabrication. It involves the meticulous process of joining metal components using heat and solder to create robust and reliable connections. The art of soldering is essential for building electronic circuits, as it ensures the seamless flow of electrical currents and enables the functionality of various electronic devices.

Key aspects of soldering joints and connections:

- Heat Application: The process begins by applying heat to the metal components using a soldering iron. This targeted application of heat facilitates the melting of the solder, allowing it to form a strong bond between the components.

- Solder Introduction: Solder, a fusible metal alloy, is introduced to the heated joint. As it melts, the solder flows into the small spaces between the metal components, forming a secure connection upon solidification.

- Precision and Control: Achieving clean, reliable soldering joints requires precision and control. Proper soldering techniques, such as controlling the amount of solder and maintaining the right temperature, are crucial for creating strong connections without damaging the components.

- Practical Techniques: Different soldering methods, including through-hole and surface-mount soldering, require distinct skills and practices. Beginners can benefit from mastering these techniques to ensure consistent and high-quality soldering joints.

- Quality Assurance: Inspecting the solder joints post-assembly is essential to ensure the absence of defects such as cold joints, which can compromise the integrity of the connection and lead to unreliable performance.

Step-by-Step DIY Soldering Projects

LED Circuit Project

An in-depth exploration of the LED circuit project provides a comprehensive guide for beginners to master their soldering skills. This step-by-step project not only reinforces basic soldering techniques but also dives into the intricacies of electronic components and circuitry. By delving into the practical application of LED circuitry, enthusiasts gain a deeper understanding of soldering and electronics, making it an ideal starting point for beginners to build confidence and proficiency in the craft.

- Explanation of LED circuit components and their functions

- Detailed soldering techniques for LED circuits

- Common mistakes and troubleshooting tips for beginners

- Advanced LED circuit project ideas for further exploration

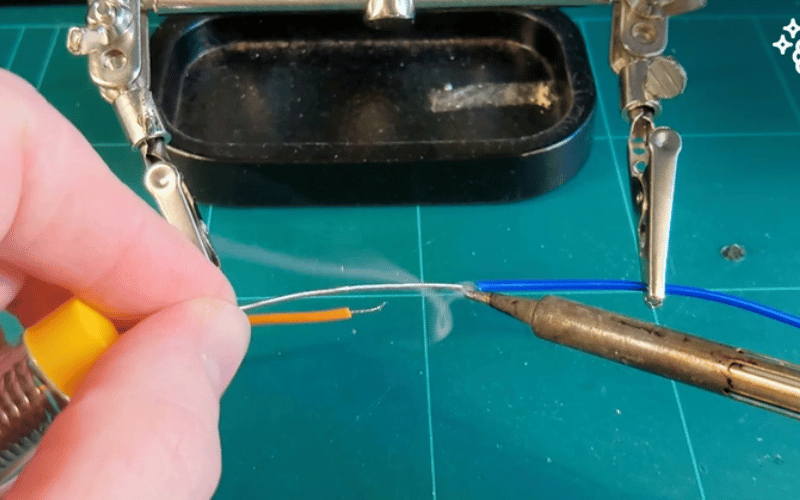

Audio Cable Repair Project

An audio cable repair project offers beginners the opportunity to practice soldering while repairing a common electronic accessory. This project not only enhances soldering skills, but also imparts knowledge on troubleshooting and repairing electronic connections. Engaging in this repair project empowers beginners with practical experience in soldering applications.

More In-Depth Information

When embarking on an audio cable repair project, it’s essential to understand the components of an audio cable and how they function. Here are some more detailed aspects to consider:

- Identifying the different types of audio cables, such as XLR, TRS, and RCA, and their specific uses in audio equipment.

- Understanding common issues with audio cables, including broken solder joints, frayed cables, and damaged connectors, and how to diagnose these problems effectively.

- Exploring the internal wiring of an audio cable and learning about the importance of proper shielding to prevent interference.

Practical Examples

Here are a few scenarios that demonstrate the practical applications of audio cable repair:

- Repairing a damaged XLR cable used in a live sound setup, ensuring that the connections are secure and the signal remains clear and stable during performances.

- Fixing a TRS cable commonly used for connecting musical instruments, guaranteeing that the cables can withstand constant movement and strain without compromising the audio signal.

- Restoring a worn-out RCA cable used in home audio systems, emphasizing the significance of proper insulation and connector integrity for optimal audio transmission.

Advanced Troubleshooting

While working on an audio cable repair project, it’s valuable to advance troubleshooting skills by:

- Utilizing multimeters and cable testers to diagnose faults, measure signal continuity, and ensure proper electrical connections within the cable.

- Learning advanced soldering techniques, such as tinning and heat shrink application, to improve the durability and longevity of cable repairs.

- Using oscilloscopes to analyze waveforms, verify signal integrity, and identify potential distortions or irregularities in the audio signal.

Common Mistakes to Avoid in Soldering

Overheating Components

One common mistake in soldering is overheating components, which can lead to damage or failure of electronic parts. It’s essential to regulate the temperature of the soldering iron and avoid prolonged exposure to sensitive components to prevent overheating. Practicing optimal temperature control safeguards electronic components during soldering processes.

- Improper soldering iron temperature settings

- Excessive contact time with the soldering iron

- Incorrect placement of heat-sensitive components

When components are overheated during soldering, several adverse effects may occur, including:

- Permanent damage to the component

- Reduced lifespan of electronic parts

- Corrosion and oxidation of the solder joints

- Diminished electrical conductivity

To prevent overheating of components during soldering, consider the following practices:

- Use a soldering iron with adjustable temperature settings

- Apply flux to improve thermal transfer

- Utilize heat sinks and thermal insulation to protect sensitive components

- Keep soldering time to the minimum required

Insufficient Flux or Solder

Insufficient flux or solder is a common mistake that can significantly impact the quality and durability of soldered connections. To ensure strong and reliable connections, it is crucial to understand the importance of using the right amount of flux and solder.

- Complete Surface Coverage: Proper application of flux and solder is essential for achieving complete coverage on the metal surfaces, which forms a strong bond.

- Adherence to Proper Techniques: Adhering to the correct soldering techniques and materials is essential to avoid the occurrence of insufficient flux or solder in DIY projects.

- Quality and Durability: Insufficient flux or solder can compromise the quality and durability of the soldered connections, leading to potential issues with the electronic circuits or mechanical joints.

- Prevention Measures: By understanding the potential consequences, hobbyists and professionals can take proactive measures to prevent the occurrence of insufficient flux or solder, thereby ensuring the long-term reliability of their projects.

Conclusion

In conclusion, soldering is an art that requires precision, creativity, and continuous learning. Prioritizing safety, practicing fundamental techniques, and embracing DIY projects are pivotal in mastering soldering. With dedication and enthusiasm, your journey through soldering projects will be as captivating as the final creations themselves.