Applying Safety Measures with Soldering Consumables Explained

Introduction

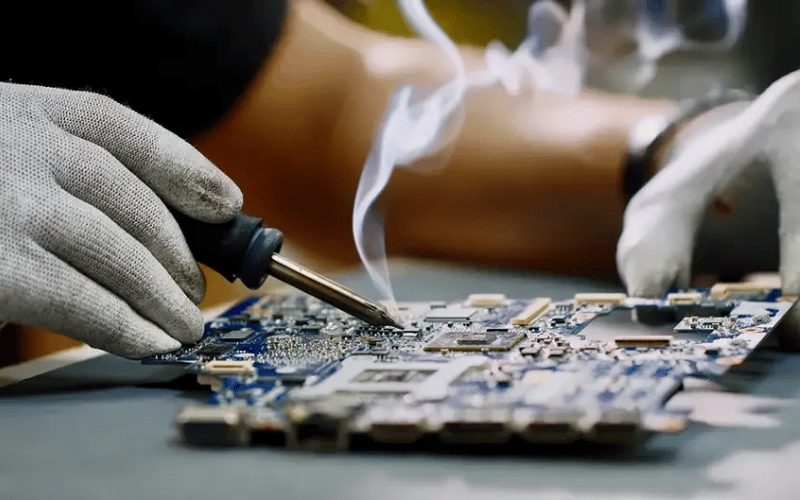

The use of soldering consumables is prevalent in various industries, particularly in electrical work. Soldering consumables encompass a range of materials and tools essential for creating strong electrical connections, such as solder wire, soldering iron, and flux. While these consumables are indispensable for electrical projects, it’s vital to recognize that they also present potential health hazards if mishandled or used without appropriate safety precautions. In this in-depth guide, we will explore the significance of safety measures and best practices for establishing a secure soldering environment.

What are Soldering Consumables?

Definition of Soldering Consumables

Soldering Consumables

- Solder Wire: This is a fusible metal alloy used to create a permanent bond between metal workpieces.

- Flux: Flux is used to prevent oxidation and facilitate the soldering process by promoting the wetting of the solder.

- Solder Paste: This is a mixture of solder alloy and flux, commonly used in surface mount technology.

- Solder Wick: Also known as desoldering braid, it is used to remove solder and components from a circuit board.

Soldering consumables are essential materials and supplies used in the process of creating strong and reliable electrical connections. The types of soldering consumables include solder wire, flux, solder paste, and solder wick. Each of these consumables has a specific function in the soldering process.

Types of Soldering Consumables

When it comes to soldering, there are various types of consumables that play a crucial role in the soldering process. Understanding the different types of soldering consumables is essential for safe and efficient soldering practices. Let’s explore some of the common types in more detail:

- Lead-Based Solder: This type of solder has been traditionally used in electronics and plumbing. It contains a combination of lead and tin, offering excellent flow and wetting properties.

- Lead-Free Solder: With growing environmental concerns, lead-free solder has gained prominence. Typically composed of tin, silver, and copper, this type of solder is widely used in electronic assemblies, ensuring compliance with regulations.

- Liquid Flux: Flux is an essential consumable used to remove metal oxides and ensure proper bonding. Liquid flux, available in various formulations, aids in oxidation prevention and enhances solder wetting.

- Solder Paste: For surface mount assembly and rework, solder paste plays a vital role. It consists of solder particles mixed with flux in a sticky paste form, enabling precise application onto PCB pads.

- Solder Wire: This consumable is widely used for manual soldering tasks. It’s a combination of flux and fine solder wire, available in different diameters to suit specific applications.

Importance of Safety Measures

Protecting Against Heat

Protecting Against Heat

When working with soldering consumables, protecting against heat is paramount. The high temperatures involved in soldering can pose a significant risk of burns and heat-related injuries if proper precautions are not taken.

- Use of heat-resistant gloves and protective clothing to minimize the risk of burns.

- Implementing proper ventilation systems to maintain a comfortable working environment.

- Utilizing heat shields and barriers to protect surrounding areas from excess heat exposure.

- Employing heat-resistant soldering mats to provide a stable and heat-resistant work surface.

Preventing Fumes Exposure

When working with soldering consumables, it’s crucial to be aware of the potential release of toxic fumes. These fumes, if inhaled, can result in various health issues, ranging from minor irritation to serious respiratory problems and long-term health effects. To effectively prevent fume exposure and ensure the safety of workers, several proactive measures can be implemented:

- Ventilation Systems: Employing efficient ventilation systems, such as fume extractors and local exhaust ventilation (LEV), helps to capture and remove fumes at the source. This prevents the accumulation of harmful fumes in the work environment.

- Respiratory Protection: Utilizing appropriate respiratory protective equipment, such as respirators with suitable filters, ensures that workers are shielded from inhaling hazardous fumes. It’s important to select respirators that are specifically designed for the types of fumes being generated.

- Work Area Design: Designing the work area with fume-generating processes in mind can help minimize fume exposure. This may involve segregating soldering tasks into well-ventilated enclosures or designated areas with controlled fume extraction.

Additionally, providing comprehensive training and awareness programs to workers about the risks associated with fume exposure and the correct usage of safety measures is essential for fostering a safe working environment.

Safe Handling of Equipment

Proper handling of soldering equipment is crucial for maintaining a safe and secure work environment. It involves a set of meticulous procedures and precautions to minimize the risk of accidents and injuries. Below are some detailed aspects of safe equipment handling:

- Insulated Tools: When working with soldering equipment, it’s essential to use tools that are properly insulated to prevent accidental electrification or burns. Insulated wire cutters, pliers, and screwdrivers are some examples of essential tools for this purpose.

- Adherence to Safety Standards: It’s imperative to follow safety standards and guidelines when handling soldering equipment. Ensuring that the equipment is in good working condition, and in compliance with safety regulations, is crucial to prevent workplace accidents.

- Proper Ventilation: Adequate ventilation plays a vital role in minimizing the risk of exposure to fumes and harmful chemicals. This can be achieved through the use of fume extractors, ventilation hoods, and well-ventilated workspaces.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as safety goggles, gloves, and protective clothing, is essential for safeguarding against potential hazards associated with soldering equipment.

Essential Safety Measures for Soldering Consumables

Choosing the Right Personal Protective Equipment (PPE)

When working with soldering consumables, it is crucial to select the appropriate personal protective equipment (PPE) to ensure safety. PPE provides a barrier between the user and potential hazards, mitigating the risk of exposure and injury. Here are key considerations for choosing the right PPE:

- Heat-Resistant Gloves: When handling hot soldering irons and materials, heat-resistant gloves are essential to protect the hands from burns and thermal injuries. These gloves should be durable and offer sufficient dexterity for intricate tasks.

- Safety Goggles: Soldering processes often produce airborne particles and splashes that can pose a threat to the eyes. Safety goggles with side shields or full-face protection are necessary to prevent eye injuries from soldering flux, molten metal, and soldering debris.

- Respiratory Protection: Inhalation of soldering fumes can be harmful to the respiratory system. Using appropriate respiratory protection, such as a respirator with the appropriate filters, is vital for minimizing exposure to fumes and hazardous airborne contaminants.

Workspace Safety Precautions

Implementing workspace safety precautions is essential for creating a safe working environment, especially when soldering. Here are some detailed safety precautions to consider:

- Maintaining a Clean and Organized Work Area: A cluttered workspace can increase the risk of accidents. It’s important to keep the work area tidy and organized, with a designated space for soldering activities. This helps in preventing tripping hazards and ensures easy access to safety equipment.

- Using Heat-Resistant Mats: Heat-resistant mats provide thermal insulation and protect the work surface from the heat generated during soldering. These mats also offer a non-slip surface, reducing the chances of the soldering station moving around unintentionally.

- Ensuring Adequate Ventilation: Proper ventilation is crucial for maintaining air quality in the workspace. Soldering produces fumes that can be harmful if inhaled. Implementing local exhaust ventilation or using fume extractors helps in removing hazardous fumes, ensuring a safe and breathable environment.

- Wearing Personal Protective Equipment (PPE): In addition to the mentioned precautions, it’s important for workers to wear suitable PPE, such as safety glasses, heat-resistant gloves, and a protective apron, to minimize the risk of injury from soldering activities.

Handling and Storage Guidelines

Adhering to proper handling and storage guidelines for soldering consumables is crucial for maintaining safety and product integrity. Below are comprehensive guidelines for handling and storing soldering consumables.

- Always wear appropriate personal protective equipment (PPE) when handling soldering consumables, including gloves, safety goggles, and a respirator if necessary.

- Handle soldering consumables with care to prevent spills and avoid contaminating the work area. This includes transporting them in secure containers and avoiding rough handling.

- Be mindful of temperature-sensitive soldering consumables and store them in a temperature-controlled environment to maintain their integrity.

- When handling lead-based solder, ensure proper ventilation to minimize exposure to harmful fumes.

- Store soldering consumables in a cool, dry place away from direct sunlight and moisture to prevent degradation and maintain quality.

- Use appropriate storage containers to keep soldering consumables organized and well-protected.

- Label all storage containers with clear identification of the contents and any relevant handling instructions.

- Consider implementing a first-in, first-out (FIFO) system to ensure older consumables are used before newer ones, reducing the risk of expiration.

Best Practices for Safe Soldering

Proper Equipment Maintenance

Maintaining soldering equipment in good condition is critical for safe soldering practices. Regular inspection, cleaning, and maintenance of soldering tools and equipment help prevent malfunctions and ensure safety during the soldering process.

- Regular Inspection: Implement a scheduled routine for inspecting soldering equipment to identify any signs of wear and tear, loose parts, or damage. This proactive approach enables early detection of potential issues, preventing safety hazards and equipment malfunction.

- Cleaning and Maintenance: Proper cleaning and maintenance of soldering tools are essential to ensure efficient operation and longevity. Use appropriate cleaning agents and methods to remove solder residue, dirt, and other contaminants from the equipment. Additionally, lubricate moving parts and replace worn components to maintain optimal performance.

- Storage and Organization: Adequate storage and organization of soldering equipment contribute to its longevity and functionality. Utilize designated storage areas with appropriate protective measures to prevent damage and corrosion. Furthermore, labeling tools and accessories enhances accessibility and minimizes the risk of misplacement.

- Calibration and Testing: Periodically calibrate soldering equipment and conduct testing to verify its accuracy and functionality. This practice ensures consistent performance and precision, reducing the likelihood of errors during soldering tasks.

Safe Soldering Techniques

Safe soldering is crucial for protecting both the health of the individuals performing the soldering work and the integrity of the electronic components being soldered. Below are some key techniques to implement for safe soldering:

- Appropriate Soldering Temperature: Always ensure that the soldering iron is set to the correct temperature for the specific type of solder being used. Using the wrong temperature can result in poor solder joints and increase the risk of damage to the components.

- Proper Ventilation: Work in a well-ventilated area or use a fume extractor to minimize exposure to solder fumes. Inhaling these fumes can lead to health issues, so it’s crucial to have proper ventilation in the soldering workspace.

- Personal Protective Equipment (PPE): Use appropriate PPE such as safety goggles and gloves to protect against solder splashes and burns. Always follow safety guidelines when working with soldering equipment.

- Minimizing Lead Exposure: If using lead-based solder, take extra precautions to minimize exposure. Wash hands thoroughly after working with lead-based materials and ensure proper disposal to prevent environmental contamination.

By incorporating these safe soldering techniques, the risk of health hazards and damage to electronic components can be significantly reduced, promoting a safe and effective soldering environment.

Conclusion

When it comes to soldering consumables, prioritizing safety is essential for maintaining a secure working environment. Understanding the intricacies of potential hazards and implementing the recommended safety measures are crucial steps in fostering a culture of safety within soldering practices. By recognizing the risks involved and proactively addressing them, individuals can contribute to a healthier and safer workspace conducive to efficient soldering activities.