Essential Soldering Iron Safety Tips for Workshops

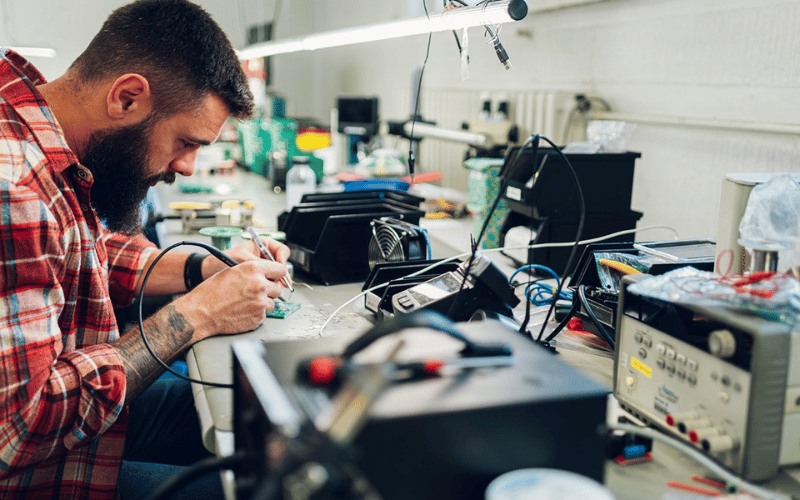

Introduction

Soldering iron safety in workshops is of paramount importance to ensure a secure and hazard-free working environment. Whether you are a beginner or an experienced user, observing safety protocols when using a soldering iron is crucial to prevent injuries and accidents. This comprehensive guide highlights the key aspects of soldering iron safety, covering essential safety practices, maintenance, and storage, to promote a culture of safety within workshop settings.

Understanding Soldering Iron Safety

What is a Soldering Iron?

A soldering iron is a hand tool used for soldering electronic components, wires, or other metal items together. It consists of a heated metal tip and an insulated handle, commonly powered by electricity or butane. The heated tip melts the solder onto the joint, creating an electrical connection or fixing a component in place.

Despite its simple appearance, the soldering iron is a crucial tool in the field of electronics and metalwork. Let’s delve deeper into the various aspects of soldering iron, including its types, uses, and maintenance.

There are several types of soldering irons, each designed to cater to specific needs:

- Standard Soldering Iron: This type is commonly used for general soldering tasks in electronics and small metalwork projects.

- Soldering Station: A more advanced version of the standard soldering iron, featuring adjustable temperature settings and additional accessories for precise and professional soldering work.

- Butane Soldering Iron: Ideal for portable soldering applications where electricity may not be readily available.

- Cordless Soldering Iron: This type offers the convenience of mobility without the restriction of a power cord, suitable for on-the-go soldering tasks.

The versatile soldering iron finds applications in various industries and hobbies, including:

- Electronics repair and assembly

- Jewelry making and repair

- Plumbing work

- Automotive repair

- Wood crafts and art projects

Proper maintenance is essential to ensure the longevity and performance of a soldering iron. Regular care includes:

- Cleaning the soldering tip to prevent oxidation and improve heat transfer

- Storing the soldering iron in a safe and stable position to prevent damage

- Replacing worn-out or damaged tips to maintain efficient soldering performance

- Using the correct solder and flux for the specific soldering task

- Adhering to safety precautions to prevent accidents and injuries

Importance of Soldering Iron Safety

Soldering iron safety is of critical importance, especially when considering the high temperatures and materials involved in the soldering process. It is essential to implement comprehensive safety measures to mitigate the risks of burns, fires, and exposure to harmful fumes. Prioritizing safety practices not only safeguards the well-being of individuals but also protects the integrity of electronic components and the surrounding environment. Understanding the importance of soldering iron safety is paramount for all those involved in electronics assembly and repair.

Essential Safety Practices

Choosing the Right Soldering Iron

When it comes to selecting the perfect soldering iron for your projects, there are several crucial factors to consider. The right soldering iron can make a significant difference in the quality and efficiency of your work. Here are some key points to keep in mind when choosing a soldering iron:

- Intended Use: Consider the specific applications for which you will be using the soldering iron. Whether it’s for electronics, plumbing, jewelry making, or other purposes, the intended use will dictate the most suitable soldering iron for your needs.

- Wattage: The wattage of a soldering iron determines the rate at which it can transfer heat to the solder joint. Higher wattage irons are suitable for larger projects and can maintain temperature more effectively, while lower wattage irons are better suited to delicate electronic work.

- Tip Size and Shape: The size and shape of the soldering iron’s tip are important considerations. Different tips are designed for specific tasks, such as fine-point tips for precision work and chisel tips for efficient heat transfer in larger joints.

- Temperature Control: Soldering irons with adjustable temperature settings provide greater versatility, allowing you to work with various types of solder and materials. Temperature control is especially crucial for sensitive electronic components.

- Type of Soldering Work: The type of soldering work you’ll be undertaking influences the choice of soldering iron. For instance, electronic soldering may require a different iron compared to plumbing or jewelry making.

By considering these factors, you can ensure that your chosen soldering iron matches the specific requirements of your projects, leading to enhanced precision and safety in your soldering work. It’s essential to choose a soldering iron that aligns with your intended use and project demands, enabling you to work with confidence and achieve optimal results.

Safety Gear and Equipment

When it comes to soldering iron safety, personal protective equipment (PPE) plays a crucial role in preventing accidents and injuries. Here’s a comprehensive list of safety gear and equipment that should be used:

- Safety Glasses: Protect the eyes from solder splashes, fumes, and other hazards.

- Heat-Resistant Gloves: Essential for handling hot components and materials.

- Fume Extractor: Helps in removing soldering fumes and maintaining a healthy workspace environment.

- Protective Clothing: Wear non-synthetic, natural fiber clothing to reduce the risk of burns.

- Closed-Toe Shoes: Provide additional protection for the feet in case of accidents.

Additionally, it’s important to ensure that the safety gear and equipment are in good condition and properly maintained. Regular inspection and replacement of damaged or worn-out gear is essential to uphold safety standards in the soldering workspace.

Proper Workspace Setup

Proper Workspace Setup

When it comes to soldering iron safety, setting up a proper workspace is paramount. Here are some detailed guidelines to ensure a safe and efficient workspace:

- Good Ventilation: Adequate ventilation is essential to disperse the fumes produced during soldering. This can be achieved by working near an open window or using a fume extractor.

- Clear Work Area: It’s crucial to maintain a clutter-free work area to prevent accidental spills and to have ample space for maneuvering the soldering iron.

- Heat-Resistant Surface: Using a dedicated soldering pad or a heat-resistant surface protects the work area from heat damage and minimizes the risk of accidental burns or fires.

- Proper Lighting: Good lighting is essential for precision work. Adequate illumination can help in accurately soldering small components and prevent eye strain.

- Protective Equipment Storage: Keep safety equipment such as goggles, gloves, and a fire extinguisher within easy reach but away from the immediate soldering area.

Safe Operation Techniques

Following safe operation techniques when using a soldering iron is essential to prevent accidents. This includes handling the iron with care, avoiding direct contact with the heated tip, and using the correct soldering techniques to minimize the risk of burns and electrical hazards.

- Always hold the soldering iron by the insulated handle to prevent electrical shock.

- Use a soldering iron stand to keep the iron stable when not in use, and never lay it down on the work surface.

- When not in use, switch the iron off and unplug it from the power source.

- Never touch the heated tip of the soldering iron with your bare hands, always use suitable tools or equipment to handle it.

- Wait for the soldering iron to cool down before cleaning, storing, or making any adjustments to it.

- Ensure the soldering iron tip is clean and tinned before use to ensure good heat transfer and reliable soldering joints.

- Use the right type and size of solder for the specific application, and avoid excessive heating of the components.

- Practice good ventilation to minimize exposure to fumes released during the soldering process.

Dealing with Emergency Situations

Being prepared to deal with emergency situations while soldering is crucial. Ensure the safety of your workspace by implementing the following measures:

- Fire Extinguisher: Have a suitable fire extinguisher within reach, and make sure you are trained in its use.

- Emergency Exits: Familiarize yourself with the layout of the building, including the location of emergency exits and evacuation routes.

- First-Aid Procedures: Understand and be prepared to execute first-aid procedures for burns and other potential injuries.

- Emergency Contact Information: Keep important contact numbers, such as local emergency services and medical facilities, readily accessible in case of urgent situations.

- Additional Safety Measures: Consider implementing additional safety measures, such as a dedicated emergency response plan and emergency response drills.

Soldering Iron Maintenance and Storage

Cleaning and Care of Soldering Iron

Maintaining a clean soldering iron is crucial not only for optimal performance and safety but also for the quality of work produced. The following comprehensive guide covers the key aspects of cleaning and caring for a soldering iron:

- Cleaning the Tip: Use a brass sponge or tip cleaner to remove any residue or oxidation from the tip. It’s important to clean the tip regularly to ensure good heat transfer and prevent soldering defects.

- Preventing Build-up: Apply a small amount of solder to the iron tip after each use to prevent oxidation and ensure a clean surface for the next job. Additionally, using a tip tinner can help maintain the tip’s cleanliness and prevent solder from sticking.

- Removing Residue: Stubborn residues can be removed by gently scraping the tip with a non-abrasive material, such as a brass wire brush or a damp sponge. Avoid using abrasive materials as they can damage the tip’s plating.

- Corrosion-free Tip: Regularly check for corrosion on the tip, and if present, use specialized tip cleaning products or a mild acid solution to restore the tip’s functionality. Proper maintenance ensures a corrosion-free tip, promoting efficient heat transfer and extending the soldering iron’s lifespan.

Proper Storage Practices

- Utilize a designated holder for the soldering iron to prevent accidental damage and injuries.

- Ensure the soldering iron is completely cool before storing to avoid any heat-related accidents.

- Consider using a heat-resistant silicone mat to place the soldering iron on during breaks in work to protect the work surface.

- Store the iron in a dry and clean environment to prevent corrosion and maintain its performance.

- Use a soldering iron stand or holder that allows for easy access and immediate recognition to avoid accidental contact with the hot tip.

- Keep the tip clean and well-tinned to prolong its lifespan and maintain optimal performance.

- Store solder, flux, and other accessories in a designated and organized container to maintain a clutter-free workspace and reduce the risk of accidental spills or damage.

- Consider using a fume extractor or proper ventilation in the workspace to minimize inhalation of solder fumes during storage.

Conclusion

In conclusion, emphasizing soldering iron safety in workshops is fundamental to fostering a secure and risk-free environment for soldering activities. By understanding the importance of safety practices, selecting the right equipment, and implementing proper maintenance and storage protocols, users can mitigate the risk of accidents, injuries, and equipment damage. Prioritizing safety not only ensures a safe working environment but also promotes a culture of responsibility and care in workshop settings.