How to Choose the Best Portable Soldering Iron: Options and Features

Introduction

Portable soldering irons have transformed the way enthusiasts and professionals approach their work, offering convenience, versatility, and efficient soldering capabilities. They cater to the demands of users who require reliable tools for on-the-go applications and field repairs. In this guide, we will explore the features and types of portable models, discuss key considerations for making an informed choice, compare the various options available, evaluate their applications across different scenarios, and highlight essential safety precautions for a secure working environment.

Understanding Portable Soldering Irons

What is a Portable Soldering Iron?

A portable soldering iron is a compact, handheld device used to melt solder and create a conductive joint between two workpieces. Unlike traditional soldering irons that are bulky and require a constant power source, portable soldering irons are designed for use on the go and are powered by rechargeable batteries, butane, or gas cartridges.

- Compact design for easy handling and portability

- Versatile power options such as rechargeable batteries, butane, or gas cartridges

- Quick heat-up time for efficient soldering on the go

- Convenient for small electronics repair, jewelry making, and DIY projects

- Temperature control features for precision soldering

Portable soldering irons come in various models and offer different temperature ranges to suit specific applications. They are widely used by hobbyists, DIY enthusiasts, electronic technicians, and professionals who require a portable soldering solution for on-the-go projects.

Benefits of Using a Portable Soldering Iron

When it comes to the benefits of using a portable soldering iron, there are several key advantages that make these devices invaluable for technicians, hobbyists, and professionals alike.

Freedom of Movement: One of the primary benefits of a portable soldering iron is the unparalleled freedom of movement it provides. Unlike traditional soldering setups, portable soldering irons offer the flexibility to work in various positions and angles. This capability allows soldering tasks to be performed with ease, even in tight or awkward spaces where conventional tools would struggle to reach.

Versatility: Portable soldering irons boast compatibility with a wide range of soldering tips and accessories, offering the versatility to handle different soldering applications. Whether it’s intricate electronics work or heavy-duty soldering tasks, these devices can adapt to the specific requirements of the job, making them an essential tool for professionals who deal with diverse soldering challenges.

Convenience in Remote Locations: The portability of these soldering irons is a game-changer for technicians and DIY enthusiasts who need to carry out soldering tasks in remote locations. In situations where access to a reliable power source may be limited or altogether unavailable, portable soldering irons ensure that repairs and projects can be completed efficiently, regardless of the surrounding environment.

Precision and Control: Advanced temperature control and ergonomic designs are key features of portable soldering irons that contribute to unmatched precision and control during soldering tasks. This results in high-quality, professional-grade solder joints and connections, enhancing the overall quality and reliability of the work performed.

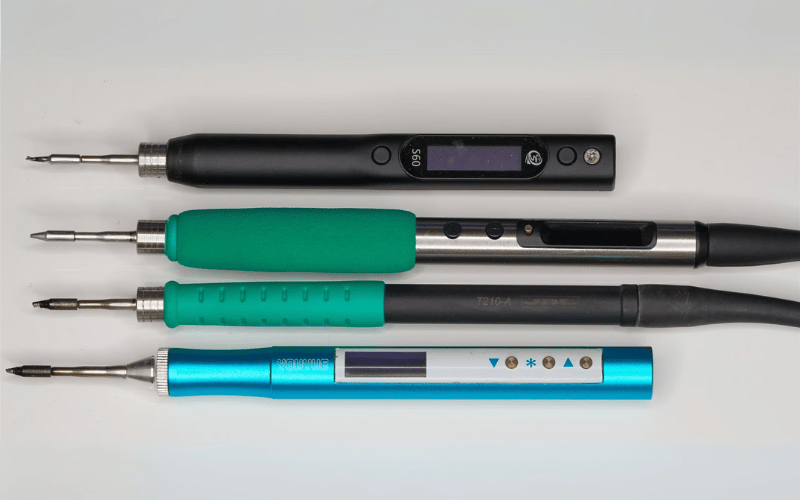

Types of Portable Soldering Irons

Gas-Powered Soldering Irons

Gas-powered soldering irons are highly versatile and convenient tools for soldering tasks. They are designed to utilize butane as a fuel source, making them suitable for outdoor use or in locations where electrical outlets are not readily available.

- Portability: Gas-powered soldering irons are known for their compact and portable nature. They are ideal for professionals and hobbyists who need to work on soldering projects in various locations.

- Quick Heating: These irons offer quick heating capabilities, allowing users to start soldering tasks promptly without the need for a lengthy warm-up time.

- High Temperatures: Capable of reaching high temperatures, gas-powered soldering irons are suitable for handling a wide range of soldering tasks, from delicate electronic components to larger joints.

- Adjustable Flame: Many gas-powered soldering irons feature adjustable flame control, providing users with the flexibility to customize the flame intensity according to the specific soldering requirements.

When using a gas-powered soldering iron, it is essential to follow safety guidelines to prevent accidents and ensure the longevity of the tool. Proper maintenance and handling of the butane fuel are crucial for the safe and efficient operation of these versatile soldering devices.

Battery-Powered Soldering Irons

Battery-powered soldering irons are an excellent choice for soldering applications that require mobility, agility, and the convenience of cordless operation. These soldering irons are powered by rechargeable batteries, making them lightweight, compact, and easy to use. They provide the flexibility to work in various locations without being tethered to a power source.

- Convenience: Battery-powered soldering irons offer the convenience of cordless operation, allowing for unrestricted movement during soldering tasks. This feature is particularly useful when working on projects in tight or hard-to-reach spaces.

- Portability: Their lightweight and compact design makes them highly portable, enabling professionals and hobbyists to transport them easily to different job sites or work areas.

- Quick Heating: These irons are designed to provide reliable and quick heating, ensuring efficient soldering for a variety of projects.

- Versatility: Battery-powered soldering irons are suitable for a wide range of soldering applications, from electronics and jewelry making to automotive repairs and other DIY projects.

For electronic enthusiasts, these soldering irons are an indispensable tool, allowing them to work on electronic circuits, wiring, and other components with precision and ease. Additionally, hobbyists and professionals in the automotive industry can benefit from the portability and performance of battery-powered soldering irons when working on vehicle repairs or modifications.

Butane Soldering Irons

Butane soldering irons are versatile tools that use butane gas as a heat source, offering portability and rapid heating capabilities. These irons are designed for various applications, including outdoor use, repairs in the field, and on-the-go soldering tasks. Let’s explore the features and uses of butane soldering irons in more detail:

- Portability: Butane soldering irons are highly portable, making them ideal for situations where access to electricity may be limited. They are commonly used by technicians and hobbyists who need to work in remote locations or outdoor settings.

- Rapid Heating: The use of butane gas allows these irons to heat up quickly, reducing downtime and increasing productivity. The rapid heating capabilities make butane soldering irons efficient for time-sensitive tasks and on-the-go repairs.

- Independence: One of the key advantages of butane soldering irons is their independent operation. Users are not restricted by power cords or battery life, giving them the flexibility to work without constraints.

- Versatility: Butane soldering irons are valuable tools for professionals and enthusiasts working in diverse environments. They are suitable for a wide range of soldering applications, including electronics repair, jewelry making, plumbing, automotive repairs, and more.

Key Features to Consider

Temperature Control

Temperature Control

- Temperature control is a critical feature that allows users to adjust the heat output of the soldering iron based on the specific requirements of the soldering task.

- This feature ensures precise and controlled melting of solder, preventing damage to delicate components and ensuring high-quality soldering results.

- It also enhances safety by allowing the user to set the temperature at an optimal level, reducing the risk of burns or overheating.

- Advanced temperature control technology provides the ability to save and recall custom temperature profiles, making it convenient for frequent use with different materials or projects.

Heating Time

The heating time of a portable soldering iron is a crucial factor to consider when choosing the right tool for soldering tasks. It refers to the time it takes for the soldering iron to reach the desired operating temperature, usually indicated in seconds. Short heating times are highly desirable as they provide immediate usability, allowing users to commence soldering tasks promptly. This is particularly advantageous in situations where time is of the essence, such as time-sensitive repair or field service scenarios.

Factors affecting the heating time of a soldering iron:

- Power Output: Soldering irons with higher power outputs generally have shorter heating times due to their ability to generate higher temperatures rapidly.

- Heating Element: The type and quality of the heating element significantly impact the heating time. Ceramic and high-quality metal heating elements are known for their quick heat-up times.

- Insulation: Proper insulation helps retain heat and can contribute to shorter heating times.

Portability and Weight

When it comes to the portability and weight of a soldering iron, these factors play a crucial role in determining the overall user experience. A lightweight and compact design not only adds to the convenience of handling but also promotes easy maneuverability, making it ideal for intricate soldering tasks in tight spaces. The portability of a soldering iron becomes paramount, especially for professionals who need to carry their tools to different work sites, as it directly impacts transport ease and storage options. Furthermore, considering the weight of the soldering iron is essential to prevent user fatigue and ensure comfort during prolonged soldering sessions. For hobbyists and DIY enthusiasts, a lighter soldering iron can make the overall experience more enjoyable and less strenuous. Therefore, selecting a soldering iron with the right balance of portability and weight is a critical decision for users across various skill levels and applications.

Power Source

The power source of a portable soldering iron significantly impacts its performance and usability. Let’s explore the different power sources and their influence on the soldering iron’s operation:

- Butane: Butane-powered soldering irons offer excellent portability, making them suitable for outdoor or on-the-go projects. They are often compact and lightweight, providing convenience for users who need mobility without sacrificing function.

- Rechargeable Batteries: Soldering irons with rechargeable batteries are versatile and environmentally friendly. They are ideal for users who prioritize sustainability and long-term cost-effectiveness. With proper charging, these soldering irons can offer consistent heating performance and extended usability.

- USB: USB-powered soldering irons are incredibly convenient, especially for individuals who work with electronic devices equipped with USB ports. They are commonly used for precise soldering tasks and are compatible with various USB power sources, such as power banks and computer ports.

Each power source has its unique benefits and considerations, and the choice depends on the specific requirements of the user and the nature of the soldering projects. For instance, an outdoor enthusiast may prefer a butane-powered soldering iron for field repairs, while a technical professional might opt for a USB-powered one for consistent performance in an office setting.

Soldering Tips and Accessories

When it comes to soldering, the availability of interchangeable tips and compatible accessories can significantly enhance the overall experience and efficiency of using a portable soldering iron. These accessories offer versatility and cater to various soldering requirements, making them essential for any soldering enthusiast or professional.

Having a range of interchangeable soldering tips is fundamental for catering to different soldering needs. The following are some common types of soldering tips:

- Conical Tip: Suitable for general-purpose soldering and precision work.

- Chisel Tip: Ideal for applications requiring efficient heat transfer, such as through-hole soldering and larger surface mount components.

- Bevel Tip: Offers a good balance between precision and heat transfer, making it suitable for a wide range of soldering tasks.

By having these different tip designs at hand, soldering enthusiasts can easily adapt to the specific requirements of each soldering project, ensuring high-quality results with improved ease and precision.

Aside from interchangeable tips, compatible accessories play a crucial role in enhancing the functionality and user experience of a portable soldering iron. Some commonly used accessories include:

- Soldering Iron Stand: Provides a secure place to rest the soldering iron when not in use, preventing accidental burns and ensuring safety.

- Cleaning Sponge: Essential for maintaining the cleanliness of the soldering tip, promoting better soldering performance and longevity.

- Desoldering Pump: Useful for removing excess solder or making corrections during the soldering process, contributing to a neater and more efficient soldering job.

- Soldering Fume Extractor: Helps to minimize exposure to potentially harmful fumes, creating a healthier and more comfortable work environment.

These accessories are designed to streamline the soldering process, increase convenience, and contribute to the overall efficiency and safety of soldering tasks.

Factors for Comparison

Performance and Versatility

The performance and versatility of portable soldering irons encompass their capability to deliver consistent heating, accomplish diverse soldering tasks, and adapt to varying work environments. Robust performance and versatile functionality ensure reliable and efficient soldering outcomes across different applications.

Battery Life and Recharge Time

When it comes to portable soldering irons, battery life and recharge time are crucial considerations. Battery life determines usage duration, while quick recharge times minimize downtime. Factors such as battery type and charging mechanism significantly impact these aspects, empowering users to make informed decisions.

Durability and Build Quality

The durability and build quality of portable soldering irons dictate their resilience in demanding work environments and under varying usage conditions. High-quality materials and robust construction contribute to the longevity and reliability of the soldering tool over time.

Price and Value for Money

The pricing of portable soldering irons in relation to their features, performance, and included accessories determines their overall value for money. Assessing the cost against the benefits and long-term utility aids in making informed decisions when investing in a portable soldering iron.

Choosing the Best Portable Soldering Iron

User Requirements Assessment

When it comes to selecting the best portable soldering iron, the user requirements assessment plays a critical role in ensuring that the chosen tool meets the specific needs of the individual. This involves a comprehensive understanding of the user’s intended applications, the frequency of use, and the nature of the soldering tasks to be performed.

- Intended Applications: Consider the diverse range of projects or tasks for which the portable soldering iron will be used. This could include electronics repair, circuit board soldering, jewelry making, or automotive repairs.

- Frequency of Use: Evaluate how often the soldering iron will be utilized. This could range from occasional use for hobby projects to frequent, daily usage in a professional setting.

- Specific Soldering Tasks: Understand the nature of the soldering work to be carried out. This may involve delicate, precision soldering on small components, heavy-duty soldering on thick wires, or a combination of both.

By delving into these user requirements, it becomes possible to identify the most suitable portable soldering iron that aligns with the user’s preferences and the demands of their projects. This tailored approach ensures that the soldering tool is not only functional but also enhances the efficiency and precision of the soldering tasks at hand.

Budget Consideration

Budget Consideration

- When selecting a portable soldering iron, budget considerations are crucial and can greatly influence the overall decision-making process.

- Understanding the budget constraints can aid in determining which features, accessories, and performance expectations align with the available financial resources.

- Cost-effective options are achievable by balancing the desired functionality with the financial parameters, ensuring that the chosen soldering iron meets both practical and economic requirements.

- Careful consideration of the budget empowers users to make informed and satisfactory purchase decisions, resulting in a successful combination of value and performance.

- In summary, evaluating the budgetary aspects ensures that the chosen portable soldering iron fulfills the targeted usage needs while offering a practical and economical solution.

Portability and Versatility

When it comes to selecting the ideal soldering iron, assessing its portability and versatility is crucial. These factors play a significant role in determining the suitability of the tool for a wide range of soldering applications. Let’s delve deeper into what portability and versatility entail:

Portability refers to the ease of transporting the soldering iron from one location to another. A portable soldering iron should be lightweight and compact, allowing for effortless mobility. This is especially beneficial for professionals who need to work at different job sites or in confined spaces.

Key considerations for assessing portability:

- Weight: A portable soldering iron should be lightweight, reducing the strain on the user during extended use.

- Size: Compactness is essential for easy storage and transportation, ensuring that the soldering iron doesn’t take up excessive space in toolboxes or workbenches.

- Handle Design: An ergonomic and sturdy handle enhances the ease of carrying the soldering iron while maintaining comfort during use.

Versatility encompasses the soldering iron’s adaptability to various soldering tasks and working conditions. A versatile soldering iron provides the flexibility to handle different soldering projects with precision and efficiency. Here are some aspects to consider when evaluating versatility:

- Temperature Control: The ability to adjust the temperature settings enables the soldering iron to cater to a wide range of soldering tasks, from intricate electronics to more robust applications.

- Interchangeable Tips: Having a selection of interchangeable tips allows the soldering iron to accommodate different soldering techniques and materials, enhancing its adaptability.

- Power Source Compatibility: Soldering irons that can operate with various power sources, such as direct AC power or portable battery packs, offer increased flexibility for diverse work scenarios.

Power Source

Choosing the right power source for a portable soldering iron is a crucial decision that directly impacts its performance and usability. There are several factors to consider when selecting the power source, and understanding the options available can help users make an informed choice.

Here are the key factors to consider when evaluating the power source for a portable soldering iron:

- Portability: Battery-powered soldering irons offer enhanced portability, allowing users to work in remote locations or areas with limited access to power outlets. Butane-fueled irons are also highly portable and can be used in outdoor settings without the need for electricity.

- Run Time: Battery-powered irons vary in run time depending on the battery capacity and power consumption. It’s essential to choose a battery-powered soldering iron with a run time that aligns with the anticipated usage duration.

- Environmental Considerations: For environmentally sensitive applications or indoor use, USB-compatible soldering irons, which draw power from standard USB ports, may be the preferred choice due to their clean and emission-free operation.

- Temperature Control: Some power sources offer more precise temperature control than others. Understanding the temperature range and control capabilities of each power source is essential for achieving the desired soldering results.

Considering these factors, it is important to align the power source of the portable soldering iron with the specific usage scenarios and user requirements. By doing so, users can maximize the efficiency and convenience of their soldering tasks.

Use Cases and Applications

DIY Projects and Repairs

When it comes to DIY projects and repairs, having the right tools at your disposal is essential for achieving quality results. One such tool that stands out for its versatility and usefulness is the portable soldering iron. Whether you are a DIY enthusiast, hobbyist, or someone involved in electronics repairs, a portable soldering iron can be a game-changer.

Here are some key points to consider about portable soldering irons:

- Portability: These soldering irons are designed to be easily portable, allowing you to work on projects in various locations.

- Versatility: They are suitable for a wide range of soldering tasks, from intricate electronics work to small appliance repairs.

- Efficiency: With quick heating elements, they enable efficient assembly, repair, and modification of electronic circuits and components.

- Applications: Ideal for soldering tasks in home workshops, maker spaces, and hobbyist setups.

Here are some common applications where portable soldering irons are invaluable:

- Electronics Repair: Whether it’s fixing a loose wire or replacing a component, soldering irons are essential for electronics repair.

- Hobby Projects: Enthusiasts working on DIY electronic projects or model making find these tools indispensable.

- Automotive Repairs: Soldering irons are handy for repairing wiring and electrical connections in vehicles.

- Jewelry Making: Precision soldering is crucial in creating intricate jewelry pieces.

By adding depth and detail to your understanding of portable soldering irons, you can fully appreciate their significance in the world of DIY projects and repairs.

Field Service and Maintenance

Field Service and Maintenance

- Portable soldering irons provide on-the-go soldering capabilities for field service technicians, maintenance professionals, and on-site repair specialists.

- They enable quick and reliable repair of electronic equipment, wiring, and connections in diverse field and industrial settings.

- With adjustable temperature controls and ergonomic designs, they enhance efficiency and precision in soldering tasks.

- The compact and lightweight nature of these soldering irons makes them highly portable and easy to use in various maintenance and repair scenarios.

- Some models come with versatile power options, such as butane and rechargeable batteries, ensuring continuous functionality in remote locations without access to conventional power sources.

Electronics and Circuitry Work

When it comes to electronics and circuitry work, having the right tools is essential for precision, efficiency, and quality results. One such indispensable tool for electronics engineers, hobbyist makers, and circuitry enthusiasts is the portable soldering iron. These advanced tools allow for precise and intricate soldering of electronic components, printed circuit boards (PCBs), and complex circuitry.

Let’s delve deeper into the significance and applications of portable soldering irons:

- Prototyping: Portable soldering irons are crucial for creating prototypes of electronic devices, allowing engineers to bring their concepts to life and test functionality.

- Repair and Maintenance: In the realm of electronics and circuitry, soldering irons enable the repair and maintenance of various devices, ensuring that they remain in optimal working condition.

- Assembly of Electronic Devices: Soldering irons play a vital role in the assembly of electronic gadgets, ensuring that components are securely and accurately connected to create functional devices.

- DIY Projects: Enthusiasts and hobbyists can leverage portable soldering irons to embark on an array of DIY projects, from creating custom electronic gadgets to enhancing existing devices.

Safety Precautions

Avoiding Burns and Injuries

When it comes to soldering, safety is paramount. To ensure safe soldering operations, there are several important measures to consider:

- Utilize a high-quality, insulated soldering iron with a heat-resistant handle to minimize the risk of burns.

- Always wear heat-resistant gloves to protect your hands from exposure to high temperatures and hot surfaces.

- Exercise extreme caution when working with high temperatures or around molten solder to avoid accidental burns or injuries.

It’s vital for soldering technicians to adhere to safety guidelines and best practices to minimize the risk of burns and injuries during soldering activities. Additionally, using a suitable work surface and maintaining a clear, organized workspace can contribute to a safer soldering environment.

Proper Ventilation and Fume Extraction

When it comes to soldering, ensuring adequate ventilation and proper fume extraction is crucial for the safety and well-being of everyone in the workspace. Here’s a more detailed look at why ventilation and fume extraction are essential:

- Health Risks: Soldering involves the use of flux and solder, which emit hazardous vapors and fumes when heated. Prolonged exposure to these fumes can lead to respiratory issues and other health problems. Adequate ventilation helps to minimize these risks.

- Workplace Safety: Well-ventilated workspaces contribute to a safer environment by reducing the concentration of harmful fumes. This is especially important in enclosed or small spaces where fumes can accumulate quickly.

- Fume Extraction Systems: Installing fume extraction systems, such as local exhaust ventilation or fume hoods, can effectively remove hazardous airborne contaminants. These systems are designed to capture and remove fumes at the source, preventing them from spreading throughout the workspace.

It’s important to note that proper ventilation and fume extraction are not only beneficial for the health and safety of individuals but also contribute to the overall quality of soldering work by creating an environment free from airborne distractions.

Safe Storage and Transportation

When it comes to safe storage and transportation of soldering irons, it is crucial to take certain precautions to ensure the well-being of individuals and the longevity of the equipment. Secure the soldering iron in a specialized heat-resistant case to protect it from external elements and prevent accidental damage. Additionally, make sure that the storage area is free from any flammable materials to reduce the risk of fire hazards. Properly label the storage area to indicate the presence of a soldering iron and educate others on the importance of handling it with care. When transporting the soldering iron, consider using dedicated carrying cases with secure closures to prevent shifting and damage during transit. Implementing these safety measures contributes to a safer work environment and extends the lifespan of the soldering iron.

Conclusion

In conclusion, the availability of portable soldering irons offers users the flexibility and convenience to undertake soldering tasks in diverse settings and applications. The selection of an ideal portable soldering iron involves assessing the performance, portability, power source, and safety features to ensure efficient, reliable, and safe soldering experiences. By understanding the benefits, types, key features, factors for comparison, use cases, and safety precautions associated with portable soldering irons, individuals can make informed decisions when investing in a soldering tool that best suits their needs and preferences.