Soldering Iron Tip Shapes and Configurations - A Reference Guide

Introduction

When it comes to the world of electronics, soldering iron tips play a pivotal role as indispensable tools for both enthusiasts and professionals alike. Their ability to provide the precision and efficiency required for a wide range of soldering tasks cannot be overstated. In this article, we will thoroughly explore the significance of soldering iron tip shapes and configurations, shedding light on why they are crucial for achieving optimal results in soldering work. We will delve into the intricate details of these tips, focusing on their shapes, configurations, and the impact of these factors on the soldering process. By understanding these key aspects, individuals can enhance their proficiency in soldering work, ultimately leading to higher quality and efficiency in their projects.

Understanding Soldering Iron Tip Shapes and Configurations

Why Soldering Iron Tip Shapes and Configurations Matter

When it comes to soldering iron tip shapes and configurations, understanding their significance is crucial for achieving high-quality soldering work. The specific shape and configuration of the soldering iron tip directly impact various aspects of the soldering process, including heat transfer, precision, and suitability for different soldering tasks.

Let’s delve deeper into why soldering iron tip shapes and configurations matter:

- Heat Transfer: The shape and configuration of the soldering iron tip determine how effectively heat is transferred to the solder joint. Different shapes and configurations have varying heat transfer properties, influencing the efficiency of the soldering process.

- Precision: Certain tip shapes and configurations offer greater precision, allowing for intricate soldering work with fine details. Understanding the role of tip shapes in precision soldering is essential for achieving accurate and clean solder joints.

- Suitability for Different Tasks: Each soldering task may require a specific tip shape or configuration to optimize the soldering process. By considering the requirements of different soldering applications, selecting the appropriate tip shape becomes critical for successful soldering outcomes.

By recognizing the impact of soldering iron tip shapes and configurations on these crucial aspects, soldering enthusiasts can make informed decisions when selecting the most suitable tip for their specific soldering needs.

Common Soldering Iron Tip Shapes and Configurations

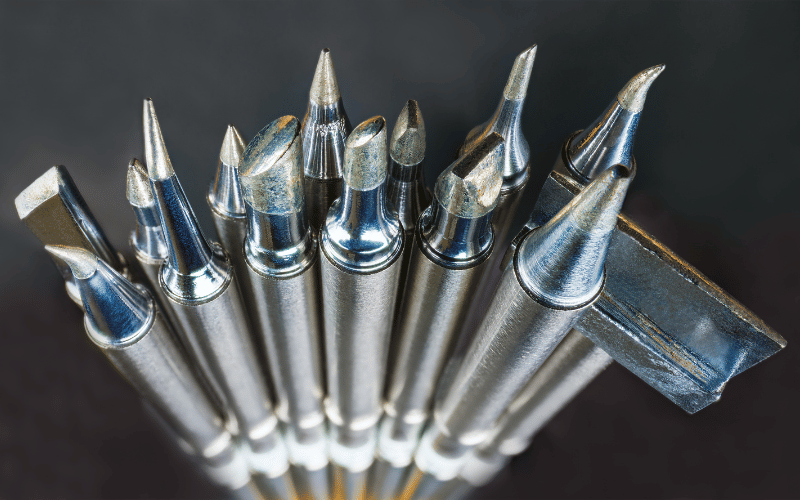

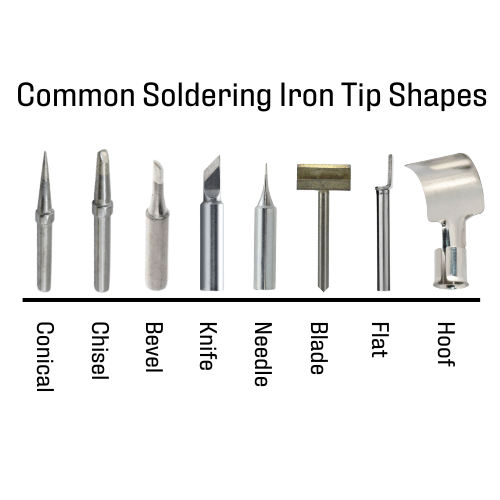

When it comes to soldering iron tip shapes and configurations, having a good understanding of the options available can greatly enhance your soldering experience. Let’s take a closer look at the common soldering iron tip shapes and configurations that you are likely to encounter:

- Conical Tips: These tips have a pointed end, making them suitable for precise soldering tasks such as working with small electronic components or creating fine connections on PCBs.

- Chisel Tips: Known for their flat, broad shape, chisel tips are excellent for transferring heat efficiently and are often used for through-hole soldering and larger joint connections.

- Bevel Tips: The sloped edge of bevel tips provides a good balance between precision and surface contact, making them versatile for a wide range of soldering applications.

- Knife Tips: These tips have a blade-like shape, allowing for precise heat application and excellent maneuverability, making them ideal for surface mount device (SMD) soldering and rework.

- Needle Tips: These tips feature an extremely fine point, perfect for very detailed work and precision tasks in tight spaces.

- Flat Tips: Designed for spreading solder over larger areas, these tips are useful when working on broad surfaces requiring uniform heat distribution.

- Hoof Tips: Designed for soldering flat surfaces, these tips have a hoof-like shape and are often used in drag soldering to handle multiple pins or components at once.

- Blade Tips: Wide and flat, these tips are useful for desoldering and soldering large components, providing extensive contact with the surface to transfer heat efficiently.

As you can see, each of these soldering iron tip shapes offers unique advantages, and understanding their characteristics is essential for selecting the right tip to suit the specific requirements of each soldering task.

Selecting the Right Tip Shape for Different Applications

Choosing the right soldering iron tip shape is a critical decision that directly impacts the quality of soldering work. Various factors need to be considered when selecting the appropriate tip shape for different soldering applications. Here, we will explore the key aspects to keep in mind for choosing the ideal tip shape:

- Solder Joint Width: The width of the solder joint plays a vital role in determining the suitable tip shape. For narrow joints, a conical tip is often preferred, while for wider joints, bevel or chisel tips may be more effective.

- Heat Transfer Requirements: Different applications may require varied heat transfer capabilities. When efficient heat transfer is crucial, a tip with greater mass, such as a chisel tip, can be advantageous.

- Type of Components: The type of components being soldered also influences the choice of tip shape. Delicate components may benefit from fine conical tips, whereas larger components may require broader tips for effective heat distribution.

Furthermore, for intricate applications, a fine-point tip enables precision, while for high-powered tasks, a broader tip can facilitate faster heat transfer. It’s essential to evaluate the specific requirements of each soldering task to select the most suitable tip shape for optimal results.

Tip Coatings and Materials

Soldering iron tips are often coated with materials such as iron, nickel, and chromium to enhance durability and soldering performance. Understanding the different coatings and materials used in soldering iron tips is essential for maintaining tip quality and maximizing their lifespan.

Types of Coatings and Materials

There are several types of coatings and materials used in soldering iron tips, each offering unique benefits and properties:

- Iron: Iron-coated tips are known for their excellent heat conduction and resistance to corrosion, making them suitable for general soldering applications.

- Nickel: Nickel-coated tips provide enhanced durability and oxidation resistance, making them ideal for high-temperature soldering and extended use.

- Chromium: Chromium-coated tips offer superior wear resistance and thermal stability, ensuring longevity and consistent performance over time.

Advantages of Different Coatings

Understanding the advantages of different coatings can help in selecting the most suitable tip for specific soldering requirements:

- Iron Coatings: Provide good thermal conductivity and corrosion resistance, making them suitable for lead-based soldering and general-purpose applications.

- Nickel Coatings: Offer excellent durability and oxidation resistance, making them ideal for lead-free soldering and high-temperature applications.

- Chromium Coatings: Deliver exceptional wear resistance and thermal stability, making them suitable for continuous use and demanding soldering tasks.

Factors to Consider

When choosing the right coating and material for a soldering iron tip, consider the following factors:

- Application Specificity: Different coatings and materials are better suited for specific soldering applications, such as electronics, plumbing, or jewelry making.

- Operating Temperature: The operating temperature of the soldering task influences the selection of the tip coating to ensure optimal performance and longevity.

- Maintenance Requirements: Some coatings may require specific maintenance routines to preserve their performance and extend their lifespan.

Maintaining Tip Quality

- Proper maintenance practices, such as cleaning and tinning, are essential for preserving the performance and longevity of soldering iron tips with different coatings and materials.

Maintenance and Care of Soldering Iron Tips

Effective maintenance and care of soldering iron tips are essential for ensuring their longevity, performance, and overall functionality. Proper care not only extends the lifespan of the soldering iron tips but also enhances their efficiency in soldering operations.

Here are some key aspects to consider for the maintenance and care of soldering iron tips:

- Regular Cleaning: Keeping the soldering iron tips clean is crucial to prevent oxidation and contamination. Utilize a brass wire cleaner or sponge specially designed for cleaning soldering iron tips. Routine cleaning helps maintain the tip’s heat conductivity and ensures a consistent soldering experience.

- Tinning: Applying a fresh coat of solder, known as tinning, to the tip after cleaning helps preserve its integrity. This process safeguards the tip from oxidation and further maintains its thermal efficiency.

- Correct Storage Practices: Proper storage of soldering iron tips is equally important. Always store the soldering iron with a properly tinned tip in a designated holder or container when not in use. This protects the tip from physical damage and exposure to air and helps retain its quality over time.

Conclusion

In conclusion, understanding the various shapes and configurations of soldering iron tips is crucial for achieving efficient and high-quality soldering results. Each tip shape has its own unique advantages and applications, and by selecting the right tip for the job, users can enhance heat transfer, precision, and overall soldering efficiency.

Whether you are working on delicate electronics or larger solder joints, there is a tip shape that is perfect for your specific project. From the fine-point conical tip for precision work to the chisel tip for larger joints, it is important to choose the right tip for the task at hand. Additionally, proper maintenance and care of soldering iron tips is essential for prolonging their lifespan and ensuring optimal performance.

We hope this article has provided valuable information on soldering iron tip shapes and configurations and has helped you understand the importance of selecting the right tip for your soldering projects. By following the tips and advice outlined in this article, you can achieve better soldering results and enhance the quality of your work. So go ahead and experiment with different tip shapes and configurations to find the perfect fit for your soldering needs!